#BlastingOperation#Hot spot#Services#wcare

The science behind Hot Spot Adjustment in shot blasting operations

Shot blasting is not just a mechanical operation; it’s a finely tuned process governed by technical principles. Proper adjustment of hot spots within the blasting wheel is crucial for achieving optimal results. This article aims to delve into the nitty-gritty of hot spot adjustment, complete with technical insights, industry standards, and advanced services offered by Winoa that can help you attain unparalleled blasting efficiency.

What is the Hot Spot?

Shot blasting

The concept of a ‘hot spot’ is universal across all shot blasting machines. The hot spot is the zone where most of the abrasives are propelled by the blast wheel, leading to a noticeable heating effect due to concentrated impacts. Knowing its location and making proper adjustments is crucial. Fine-tuning involves directing the flow of the abrasive shots using various identification methods, aiming to ensure the blast wheel delivers the maximum amount of abrasive to the intended target area.”

Understanding the hot spot is essential for maximizing efficiency and precision in any shot-blasting operation. It’s not just about directing the shots but making sure they hit the right spot with optimal force for effective surface preparation or treatment.

Why Hot Spot adjustment matters?

Poorly adjusted hot spots can lead to significant drawbacks that affect both the machine and the part being processed. If the abrasive shots miss their intended target, they won’t effectively descale the part, leaving residual sand, scale, rust and impairing cleanliness. This can wear down machining heads prematurely, raising operational costs. This is especially concerning for parts requiring coatings, as poor adhesion points can compromise durability.

Moreover, an improperly aligned jet of abrasives can cause premature wear on the machine’s deflector shields, or liners, and leading to increased abrasive consumption. Uneven energy distribution across the abrasive media can result in inconsistent surface finishes and accelerate machinery wear.

Furthermore, poor hot spot adjustment can destabilize the operating mix. The wrong jet placement produces finer particles, which wear out the machine’s blades quicker and escalate maintenance costs.

On average, the impact of poor hot spot alignment includes:

- 10%+ increase in abrasive consumption

- 15% reduction in shot blasting efficiency

- An additional 5%+ wear on the shot blasting cabin’s shields

- 20-25% increase in total shot blasting costs

Adjusting hot spots is not just profitable but vital for enhancing shot blasting quality and minimizing machine maintenance costs. For a tailored approach to your shot blasting operations, consider utilizing Winoa’s technical services.”

Understanding the implications of poorly adjusted hot spots is crucial. It’s not just about machine maintenance, but it also has direct effects on the quality and cost of your operations. Are you currently employing any specific methods to monitor and adjust the hot spots in your shot blasting machines?

Methodology for Hot Spot adjustment?

Several methods exist for controlling the hot spot to optimize both shot blasting quality and machine performance. Traditional methods include manually touching the blasted part to feel for the hottest area or using painted steel sheets, both of which are subjective and imprecise. Almen strips offer more precision but can be time-consuming.

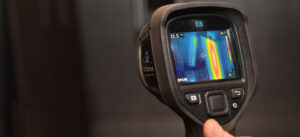

The most accurate and efficient solution is WA CAM, a thermal camera technology by Winoa. This tool converts heat generated by radiation into an image, making it straightforward to pinpoint the hot spot and other areas of wear. Originally designed for electrical and mechanical sectors, it has been adapted for shot blasting with a pistol camera and an iOS version.

Regular hot spot checks are advisable during blade or blast wheel replacements, shot changes, or when altering the type of parts blasted. The direction of the abrasive shot is influenced by blade wear, so replacing worn blades can change the hot spot location. The type and size of the abrasive used can also impact the hot spot.

To adjust, simply reposition the control cage manually. The hot spot is usually located around one-third of the shot blast pattern. Consistent monitoring and adjustments can greatly improve blasting quality and minimize machine wear and abrasive consumption. For specialized guidance, reach out to Winoa’s W Care service, experts in shot blasting operations.

By understanding and employing the right methodology for hot spot adjustments, you can significantly improve the efficiency and longevity of your shot blasting operations. Are you currently using any of these methods, or would you be interested in adopting more advanced techniques like WA CAM?

Ready to optimize your shot blasting operations? Contact us to schedule an appointment and take the first step toward achieving unparalleled efficiency in your shot blasting processes.