Success Story: A successful long term partnership between the metal casting division of PSA Group and WINOA.

Cost reduction of blasting operations:

When considering these two groups, one can’t help but notice the similarity of their commitments: safety, quality, and environment, three points of focus that played a significant role in this meaningful encounter and that are mapping the road of a successful collaboration.

Faced with a highly competitive market, be it in the automotive industry or in the steel industry, and more particularly in the production of shot media, constant innovation is essential. The metal-casting divisions of the PSA Group and WINOA are well aware of this, and it is this shared ambition that drew them together and provides the driving force of their collaboration.

For PSA foundries, innovating is to enhance their production range, by manufacturing new and cutting-edge parts in addition to their traditional production.It also means developing new production processes and new materials and implementing European standards governing the emission of air pollutants. For WINOA, innovating means developing new products and enabling their clients to continuously improve their processes. It also means developing technologies that will allow their clients to reduce the global cost of their blasting operations.

Finally, headed by a team of technical experts, it means providing their clients with the support they need through consultancy, training and testing services. Driven by shared ambitions of excellence, these two key-players had no other choice but to join forces! This is how the Charleville metal-casting division of the PSA Group and WINOA were able to leverage their collaboration:

The introduction of Premium Products for constantly-innovating solutions

Through the exclusive combination of a Premium Product, guaranteeing enhanced performance compared with standard products, and an associated Premium Service, guaranteeing optimal use of this product for the best possible results in terms of quality and cost, WINOA launched its collaboration with the metal-casting division of the PSA Group.

This collaboration dates back to 2001 when the technical teams of W Abrasives introduced the HPG, a Premium Product for foundries, on PSA’s Sept Fons site. The product was developed for the purpose of improving the quality of grit removal operations and reducing the costs of blasting – a challenge that was overcome!

In 2003, the Charleville-Mézières site and its “crankshaft” line took full advantage of the support provided by the W Abrasives teams and the introduction of the HPG; here again, the results proved satisfactory and the foundry decided to implement HPG for all of its grit removal lines. Until 2010, the HPG product was met by constant success. From then on, to satisfy new shot blasting constraints facing PSA’s metal-casting division, both industrialists turned their sights to a new challenge: researching, testing and launching a new Premium Product.

In 2011, Stainium SM 318 is tested with a view of replacing WS 460 shot media. The Charleville foundry and WINOA set themselves a double goal: improving the cleanliness of parts and using a single shot blasting line to blast differential housings. To ensure the feasibility of the project, tests were conducted at WINOA’s Le Cheylas Testing Center, and on the BMD line of Charleville. When all the results were shown to be conclusive and validated, the foundry of the PSA Group decided to keep the Stainium SM 318 for both its foundry lines, until the “GF” tank was ended in 2015.

Improvement and cost reduction of blasting operations

For the purpose of constantly improving our services, new tests were conducted in 2015 to reduce the cost of parts, reworks and maintenance operations on all PSA product references that traditionally underwent a double grit removal process (housings, manifolds, pivots…). These parts must undergo complete grit removal and cleaning before being shipped off for machining operations at the Valenciennes and Metz sites. To prevent abnormal tool wear, the last grain of sand must be removed from the surface of the parts, and rigorous cleaning must be guaranteed.

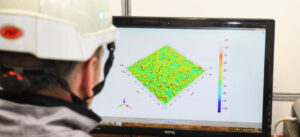

The Le Cheylas Testing Center is where the technical experts of W Abrasives conducted a technical and financial study of the validated solution using the SM 318 premium product. Thanks to the WA COST technology, WINOA quantifies the different cost items relating to blasting operations and identifies cost reduction opportunities. It was therefore able to offer the Charleville foundry a substantial reduction of its blasting costs. The W Abrasives teams also work on ways of optimizing the machine and implementing industrial tests. Following the industrial testing phase, parts sent to the machinists are validated.

The second blasting process on the WST 28 finishing line is no longer needed; today, the required level of cleanliness is achieved after only one blasting operation; the goal is once again achieved. This is evidence of a harmonious relationship and brilliant team work by the PSA Group Charleville site and WINOA!

Gain/Cost reduction achieved by the PSA Group’s metal-casting division: between €30 and €40 K

To ensure constant part quality prior to machining operations, the Charleville foundry integrates the WA CLEAN technology introduced by WINOA, which enables to read, measure and log the level of cleanliness of blasted parts before coating. This process allows the foundry to conduct its cleanliness measurements before machining operations, and therefore to secure its process.

Therefore, thanks to WA CLEAN, the Charleville foundry pushes the boundaries of optimization of its machine parameters and achieves further gains on its blasting costs.

Today, the Charleville site of the PSA Group has two WA CLEAN.

Client support is a great technological and human adventure. Team work is a rewarding process – pooling the experience of the foundry division teams of the PSA group and WINOA opens the door to continuous improvement of their processes, and provides the guarantee of high-quality products to our clients, to earn their trust, as we know that a satisfied client is a loyal client.

Client satisfaction is by nature temporary; at WINOA, client support is a long-term commitment – of course, this is not a risk-free process, and new challenges can rise at any moment, but when WINOA makes a commitment, a dialog is established, our teams are attentive to our clients’ needs, the technical approach is mastered and a customized solution is always offered. The foundries of the PSA Group are safe in their knowledge that WINOA’s customer support is the best possible bet.

WINOA would like to thank the foundry division of the PSA Group for its trust and is delighted that we have completed part of the journey to success together!