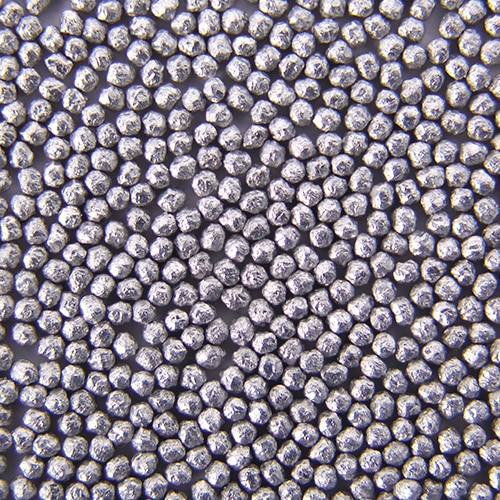

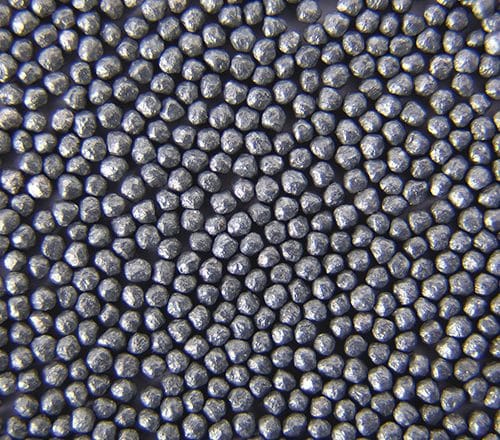

Zinc Cut Wire: Superior Corrosion Protection

Versatile abrasive for delicate surface treatments

Zinc Cut Wire is an exceptional abrasive medium, specifically designed for paint removal, deflashing, and deburring applications. It is ideal for treating delicate substrates such as aluminum and magnesium castings, minimizing the risk of damage. Zinc Cut Wire is also gentle on shot blast machinery, reducing overall wear and tear.

This product is available in two chemical compositions: pure zinc (a softer option) and zinc alloyed with aluminum (98%/2%) (a harder option), providing versatility to suit your specific application needs.

Features and Benefits:

Features and Benefits:

Maximize efficiency in gentle surface preparation

Zinc Cut Wire offers a range of features and benefits designed to enhance your surface preparation processes. From superior corrosion resistance to consistent performance, discover how Zinc Cut Wire can improve your operations.

Gentle yet effective

Benefit:

Safely removes coatings and defects without damaging the substrate.

Description:

Zinc Cut Wire is soft, providing efficient paint removal and deflashing while preserving the integrity of delicate parts.

Low Dust Generation

Benefit:

Suitable for various surface preparation tasks.

Description:

Ideal for deburring, deflashing, and paint stripping on a range of materials including aluminum castings, aluminum forgings, and magnesium castings.

Quality

Benefit:

Made from high-purity zinc, ensuring consistent performance.

Description:

Utilizing 99.995% pure zinc, Zinc Cut Wire offers reliable and uniform results, leaving a fine zinc film for added corrosion protection.

Performances

Performances

The Ultimate Choice for Corrosion Protection

Zinc Cut Wire delivers outstanding performance in various applications. Its effective cleaning capabilities, consistent abrasive action, and electrochemical protection ensure superior results, making it the preferred choice for gentle industrial surface preparation.

1. Effective Paint Removal:

- Performance: Efficiently strips paint and powder coatings without damaging the underlying material.

- Impact: Leaves a fine zinc layer, facilitating easier future paint removal and providing corrosion protection.

2. High-Quality Deflashing:

- Performance: Removes flash up to 0.020 inches from parts.

- Impact: Achieves a bright, clean finish on aluminum and titanium parts, ensuring high-quality results without imparting ferrous material.

3. Precise Deburring:

- Performance: Smoothly deburrs die castings, ensuring surface uniformity.

- Impact: Enhances the finish and functionality of cast parts, critical in high-precision applications.

4. Reduced Operating Costs Compared to Non-Metallic Media:

- Performance: Durable and efficient, reducing media consumption and equipment wear.

- Impact: Offers cost advantages over non-metallic media like glass beads, with longer-lasting performance, less waste due to durability so less disposal costs of fines and dust.

Key Advantages

Key Advantages

Zinc Cut Wire

- Corrosion resistance: Our Zinc Cut Wire provides exceptional corrosion resistance, making it an ideal choice for cleaning and finishing applications in various industries.

- Soft vs. Hard variants: We offer two distinct types of Zinc Cut Wire:

- Soft: Designed for gentle surface preparation, minimizing the risk of damage to delicate components.

- Hard: Engineered for more aggressive applications, providing effective cleaning while maintaining the integrity of the substrate.

- Electro-Chemically neutral : Our Zinc Cut Wire is electro-chemically neutral when used on aluminum and magnesium alloys, effectively preventing white corrosion and maintaining the integrity of your components.

- Safe residues : Unlike steel shots, the residues from our Zinc Cut Wire will not cause damage or fractures to milling, drilling, or threading tools.

- Minimized parts deformation : Reduce deformation during the blasting process, particularly on thin-walled castings. This is especially important for parts with cooling fins, which are prone to deflection under stress.

Markets and applications

Markets and applications

Optimized for delicate materials

Zinc Cut Wire offers versatile and high-performance solutions tailored for various markets and applications. Its unique properties make it ideal for delicate surface treatments such as paint removal, deflashing, and deburring, ensuring precise and effective results. Whether working with aluminum castings, magnesium components, or die castings, Zinc Cut Wire provides great performance with lower risks of damaging the substrate vs all other metallic medias. Explore the benefits it brings to your specific industry needs, enhancing the quality and efficiency of your operations.

Automotive

Aluminum Castings and Forgings

Aerospace

Magnesium components

Die Castings

Deburring and deflashing operations.

Specifications

Specifications

Detailed specifications for precision and quality

Below you will find the range available as standard of our Zinc Cut Wire . Typically standard in 2 compositions. Other composition, dimensions, hardness, and specifications available on request.

Typical specifications:

| Parameter | Specification | Specification |

|---|---|---|

| Material Composition | Pure Zinc

99.995% High-Purity Zinc (ISO 14919) |

Zinc-Alloyed

98% Zn / 2% Al |

| Hardness | approx 30–45 HV0.1 | New: ~40 HV

Conditioned/rounded: 60-85 HV |

| Density | 7.14 g/cm³ | |

| Bulk Density | 4.8-5.2 g/cm³ | |

| Sizes Available | 0.6 mm to 1.8 mm

0,6 mm 1,1mm |

|

| Shape | Cylindrical with sharp edges

Rounded (G2) |

|

| Packaging Options | 25 kg bags standard. 30-gallon drums, 55-gallon steel drums, 10 kg bags on request | |

| Standards Met | DIN EN 573-3 | |

Enhance Your Surface Preparation with Zinc Cut Wire

Enhance Your Surface Preparation with Zinc Cut Wire

Conclusion

Zinc Cut Wire offers superior performance in paint removal, deflashing, and deburring for delicate materials. Its gentle yet effective properties, combined with high purity and consistent results, make it an ideal choice for a wide range of industrial applications.

Contact us today to request a quote or learn more about how Zinc Cut Wire can enhance your surface preparation processes.

You may also like

You may also like

Technical Frequently Asked Questions (FAQ)

Technical Frequently Asked Questions (FAQ)

Zinc Cut Wire

Zinc Cut Wire typically has a hardness range of 20-30 HRB. This relatively low hardness allows it to effectively deburr without damaging the substrate. It smoothly removes burrs and flashes from soft materials like aluminum and magnesium castings, ensuring a clean finish and preserving the integrity of delicate parts.

Zinc Cut Wire offers gentler abrasive action compared to aluminum oxide abrasives. While aluminum oxide is highly aggressive and can damage soft substrates, Zinc Cut Wire effectively removes paint and coatings without causing harm. This makes it ideal for stripping paint from delicate materials like aluminum and magnesium, maintaining surface integrity.

Zinc Cut Wire is particularly suited for deflashing aluminum die castings due to its softness and non-sparking properties. Unlike harder metallic abrasives, it removes flash without embedding into the substrate or causing microcracks. Additionally, it leaves a protective zinc film, which enhances corrosion resistance, an advantage not provided by other metallic abrasives.

Zinc Cut Wire complies with standards such as DIN EN 573-3, which specifies the chemical composition and mechanical properties of wrought aluminum and aluminum alloys. Adherence to these standards ensures consistent quality and performance, providing reliability in industrial applications where precision and material integrity are crucial.

Zinc Cut Wire acts as a sacrificial anode when used on steel substrates. Its electrochemical behavior allows it to corrode preferentially, protecting the steel from corrosion. This sacrificial action is particularly beneficial in harsh environments, providing an additional layer of protection and extending the lifespan of steel components.