Technological transformation for energy efficiency and sustainability in steel shot manufacturing at Winoa Thailand

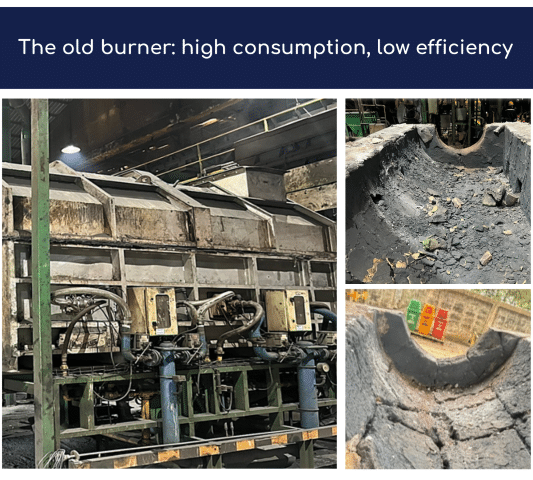

At its Ermatt site in Thailand, Winoa has enhanced both its productivity and environmental commitment through investments in cutting-edge technology. This transformation, driven by the installation of new self-recuperative burners and modern furnace insulation, reflects Winoa’s vision of combining operational excellence with environmental responsibility.

Discover our Winoa Thailand site

A technological revolution at the heart of the Ermatt industrial site

The centerpiece of this project is the installation of five ECOMAX self-recuperative burners, each with a capacity of 180 kW. These next-generation systems are designed to reduce gas consumption while increasing furnace efficiency by recovering waste heat.

Additionally, the furnace insulation has been completely modernized using high-performance materials, including ceramic fibers and Cast 13 LW, significantly reducing heat loss.

Prasertsri Saithong, Plant Manager at Winoa Thailand, states:

This project goes beyond a simple upgrade; it’s a true revolution in how we manage energy and quality control.

Tangible and impressive results in production

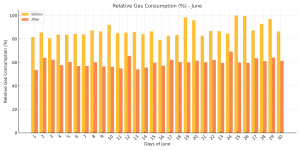

The improvements made at the Ermatt site are reflected in numbers that speak for themselves:

- Enhanced energy efficiency:

Gas consumption dropped by 34%, from 388.57 kWh/ton to just 255.85 kWh/ton, generating an estimated annual savings of €112,000. - Reduced carbon footprint:

Thanks to these new installations, CO₂ emissions decreased by 497.4 tons annually, equivalent to planting thousands of trees! - Increased productivity:

Production capacity rose by 12%, enabling an additional 6 tons of output per day. - Improved quality:

The optimized furnace temperature stability ensures consistent operations and enhanced product quality.

Toward a Greener and More Efficient Future

This ambitious project is part of Winoa Thailand’s broader sustainability strategy. However, the company is not stopping there. Planned next steps include:

- Studying the feasibility of quenching larger-sized parts to further increase production capacity.

- Reducing the use of electric quenching systems to maximize energy savings.

- Training teams on new operational standards to fully leverage these technological advancements.

These initiatives demonstrate Winoa’s unwavering commitment to fostering a more responsible and innovative industrial future.

A Model for the Shot Blasting Industry

With this technological transformation, the Ermatt site in Thailand has become a model of excellence in innovation and energy efficiency. This project perfectly illustrates how operational performance improvements can go hand in hand with reducing environmental impact.

Want to learn more about our environmental commitments?

Discover our Green Pledge initiative and our vision for sustainable surfaces