Test For Success: Optimizing Abrasive Selection

Abrasive selection plays a crucial role in surface preparation, impacting efficiency, cost-effectiveness, and final surface quality. This article, written by Chris Prouty for MFN Magazine MFN: International Metal Finishing News, explores the evolution of blasting techniques, the advantages of smaller abrasives, and the role of test centers in optimizing selection processes. Through industry insights and a real-world case study, we highlight how businesses can make data-driven decisions to enhance productivity and reduce costs.

Transitioning to Smaller Abrasives: A Game Changer

Traditional large abrasives were once the norm due to slower blast wheel technology. Today, high-speed centrifugal blast wheels enable the use of smaller abrasives, offering better coverage, lower consumption, faster cleaning times, and cost savings. Despite these benefits, companies often hesitate due to concerns about performance, quality, and switching costs.

Impact of size & impact energy on surface prep

The role of shot blasting test centres

To mitigate risks, shot blasting test centers provide a controlled environment for evaluating abrasives under real production conditions. This ensures data-driven decisions by analyzing:

- Cleaning speed and efficiency

- Material consumption

- Surface profile results

Key Benefits of Testing Abrasives

- Lower risks: Avoid costly mistakes by testing before large-scale use.

- Cost efficiency: Optimize material consumption and reduce operational costs.

- Increased productivity: Find the most effective abrasive for specific tasks.

- Customization: Ensure abrasives match industry requirements.

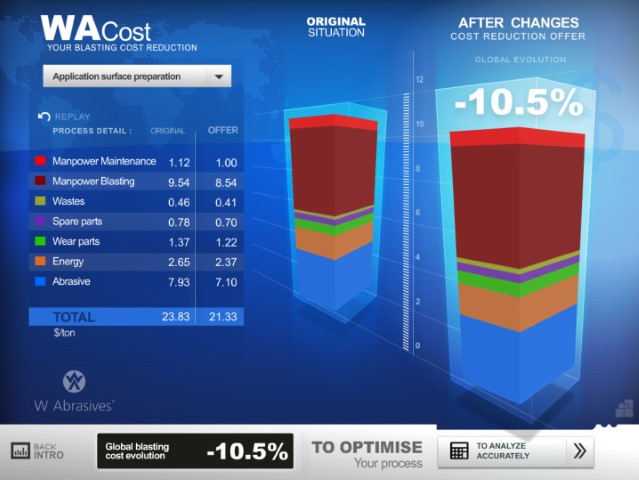

Success Story: Smaller Abrasives, Bigger Gains

A steel fabrication company transitioned from S330/G25 to S230/G40 after conducting tests at a shot blasting test center. The results demonstrated significant improvements:

- Abrasive consumption decreased by 10%

- Cleaning speed increased by 15%

- Surface quality was maintained with a higher peak count

| Shot/Grit | Nominal Dimension (inches) | Nominal Dimension (mm) | Impacts per lb (new shot) |

Impacts per lb (operating mix) |

% Increase in Impacts (vs. Larger Size) |

| S-780 | 0.0787 | 2.00 | 11,000 | 51,000 | – |

| S-660/G12 | 0.0661 | 1.70 | 19,000 | 97,000 | 90% |

| S-550/G14 | 0.0555 | 1.40 | 32,000 | 118,000 | 22% |

| S-460/G16 | 0.0469 | 1.18 | 54,000 | 240,000 | 103% |

| S-390/G18 | 0.0394 | 1.00 | 93,000 | 406,000 | 69% |

| S-330/G18 | 0.0331 | 0.85 | 152,000 | 731,000 | 80% |

| S-280/G25 | 0.0280 | 0.71 | 250,000 | 1,308,000 | 79% |

| S-230/G32 | 0.0231 | 0.60 | 420,000 | 2,850,000 | 118% |

| S-170/G40 | 0.0165 | 0.43 | 1,200,000 | 4,750,000 | 67% |

| S-110/G50 | 0.0117 | 0.30 | 3,300,000 | 9,200,000 | 94% |

| S-70/G080 | 0.0070 | 0.18 | 12,000,000 | 30,000,000 | 226% |

Conclusion: A Smart Path to Optimization

Adopting smaller abrasives enhances efficiency, reduces costs, and maintains high-quality surface preparation. Test centers help companies make informed decisions, ensuring a competitive edge in abrasive blasting.

Complete Insights on Abrasive Selection and Optimization

Download the full article

For a more in-depth exploration of abrasive selection, cost savings, and efficiency improvements, access the full article written by Chris Prouty for MFN Magazine.

MFN Article : optimizing Abrasive Selection