Maintaining a balanced operating mix is critical in the process of blast cleaning metal. Achieving this requires the proper functioning of all aspects of a blast machine. A well-balanced abrasive operating mix, consisting of a blend of abrasive sizes, ensures efficient and cost-effective blasting operations.

Understanding the operating mix

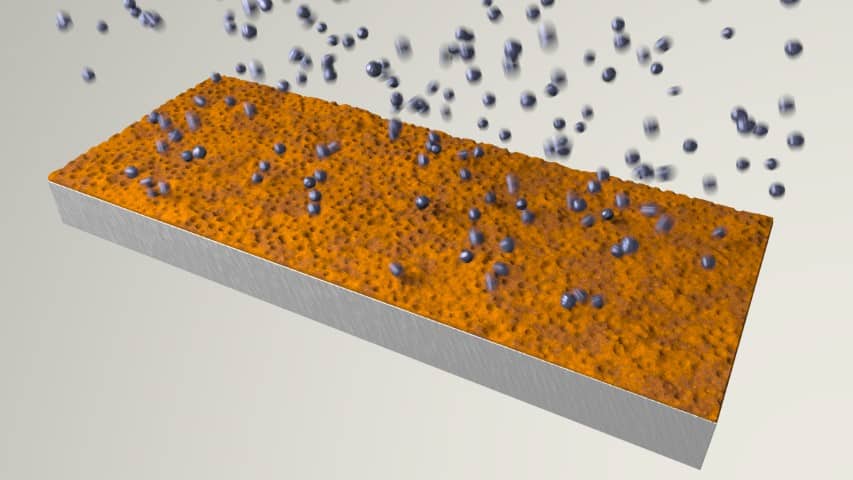

The abrasive operating mix, or working mix, combines new, partially worn, and nearly spent abrasives with debris and dust.

For efficiency, it should have a balanced blend of large, medium, and small abrasive particles, free from unwanted materials.

The specific mix depends on the application and equipment condition.

What are the key components of a balanced Operating Mix (OM)?

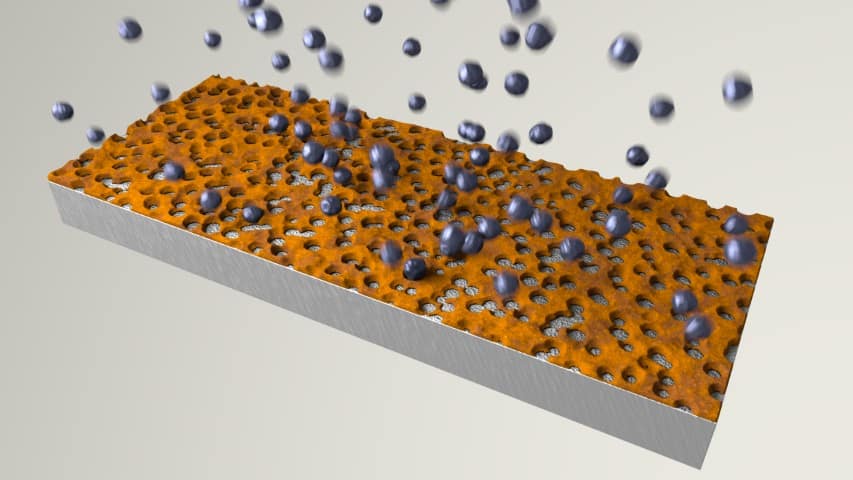

New abrasives (Large):

- Provide the initial impact force to break through tough contaminants and create the primary surface profile.

- Essential for establishing the initial anchor pattern for coatings.

Partially worn abrasives (Medium):

- Maintain consistent cleaning efficiency and contribute to the surface profile.

- Balance impact force and coverage, ensuring proper surface preparation.

End of life abrasives (Small):

- Ensure thorough coverage by reaching small crevices and removing finer contaminants.

- Refine the surface profile to meet coating adhesion specifications.

*No Dust or Unwanted Particles: The balanced operating mix excludes dust and ineffective small particles, ensuring each abrasive component functions efficiently and properly without contaminating the surface.

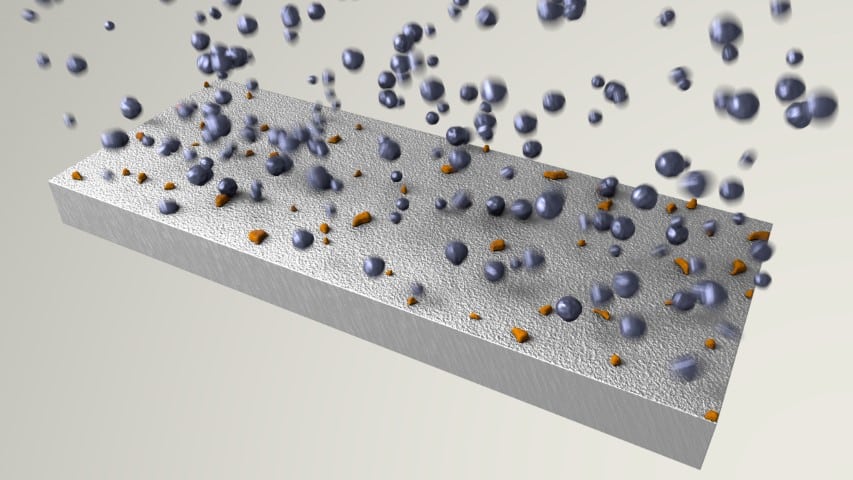

Maintaining the Operating Mix (OM)

To ensure optimal system performance, maintaining a consistent operating mix involves four key areas, managed by the operator or an automatic system:

Set the Separator

- Function: Remove spent abrasives and fines.

- Importance: Ensure the mix remains effective and free of non-functional particles.

Control Abrasive Leaks

- Function: Return leaked abrasives to the machine regularly, and plug any leaks.

- Importance: Minimize loss of abrasive materials, maintaining an effective mix.

Minimize Carry-out Losses

- Function: Keep carry-out to a minimum and return the abrasive to the machine if feasible.

- Importance: Reduce waste and ensures continuous use of effective abrasive particles.

Control Abrasive Additions

- Function: Frequently add new abrasives in small quantities to match the breakdown rate.

- Importance: Maintain a balanced mix by compensating for abrasive losses due to breakdown, separator take-out, leaks, or carry-out.

To learn more, discover our article: 3 reasons to maintain your Separator System

Results of a balanced operating mix

In the modern manufacturing industry, controlling costs is crucial. By maintaining a balanced operating mix, you will achieve:

- Enhanced cleaning efficiency: Effectively removes contaminants, ensuring cleaner blasted parts.

- Consistent surface profile: Provides uniform surface roughness, improving coating adhesion and quality.

- Reduced abrasive consumption: Minimizes waste, prolonging the life of abrasives, and lowering costs.

- Improved equipment performance: Reduces wear and tear, extending the lifespan of machine components *

- Cleaner air: Reduces dust and particulate matter around the machine, improving the work environment.

- Cost savings: Lowers operational costs and increases profit margins.

- Optimal coating performance: Enhances durability and effectiveness of applied coatings

Understanding and maintaining the operating mix is a simple yet effective strategy to enhance productivity and efficiency in blast cleaning operations.

* It is commonly known that having 2% sand in an operating mix results in a 50% increase in maintenance and wear on your equipment.

Learn how to lower operational costs and increase profit margins

The Blast Check kit

Your solution for optimal blasting

To simplify the monitoring and optimization of your operating mix, consider using the Blast Check Kit. This tool allows you to sample and analyze your operating mix accurately, ensuring superior performance and cost-effectiveness in your blasting projects.

Conclusion

In the shot blasting process, maintaining a balanced operating mix is essential for achieving high productivity and efficiency. Utilizing tools like the Blast Check Kit can significantly enhance the monitoring and optimization of your operating mix, leading to better blasting results and cost savings. Understanding the processes and consistently maintaining the machine functions are key to unlocking superior performance in blasting operations.

Find the full article in English by our Technical Advisor at Winoa, Nick King