We often hear that it is dangerous to use grit in a Wheelblast machine. It seems that the grit would destroy the equipment and the life of the turbines.

However, we lose all the benefits of the efficiency that an angular shot can bring us.

Why peen when you want to descale and create an anchor profile before surface preparation?

W Abrasives produces an angular shot which will ultimately allow you to reach your surface preparation objectives if you use round shot.

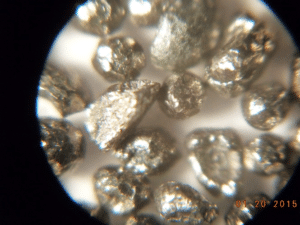

1- Shape of the abrasive:

2- Production efficiency:

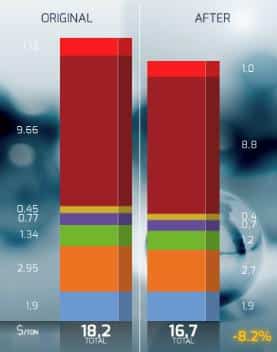

3- Consumption:

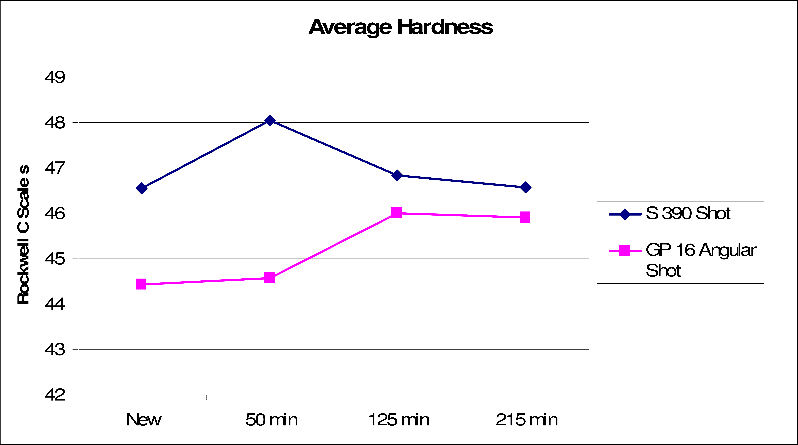

4- Lesser Hardness:

5- Maintenance Costs:

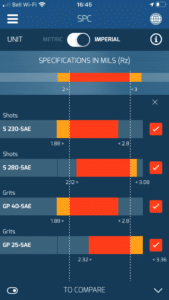

6- Profile height:

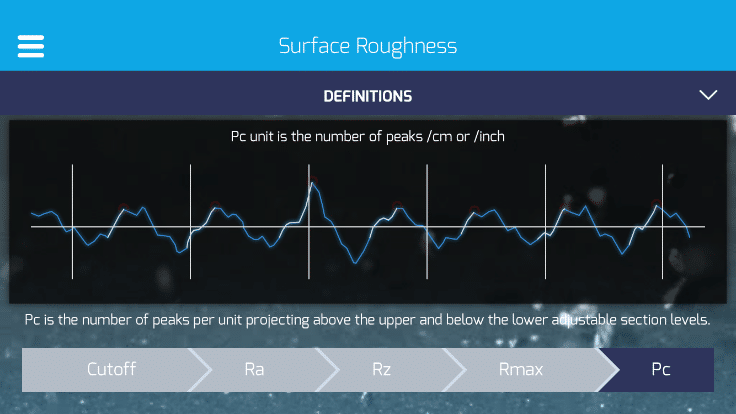

7- Higher Peak Count:

8- Total Costs:

Due to the increased cleaning efficiency, cycle times are reduced having a direct impact on production costs. In addition, electricity and maintenance costs will decrease with increased performance. Typically, we get a total cost reduction of around 8%!

As presented here, the GP angular shot will allow you better and more beautiful blasting results than shot at equivalent size, with improved surface profiles while reducing your blasting costs.