Success Story of Daewoo Shipbuilding & Marine Engineering (DSME) for ship’s outside blasting surface

Daewoo Shipbuilding & Marine Engineering (DSME) won the tender to build 15 ice breakers to transport liquefied natural gas (LNG) for Russia’s Yamal project worth some trillion KRW. This huge project started in November 2015 and will carry on till the middle of 2018.

DSME, one of the biggest shipbuilding companies in the world, had been using Pro58 and normal grit. For the project they required a suitable grit that would not cause any sticking risk on ship’s outside blasting surface for the special paint demanded from inspectors. To fit their specifications, SSK proposed to use a special Profilium specifically designed for the project that they named “Yamal Profilium”.

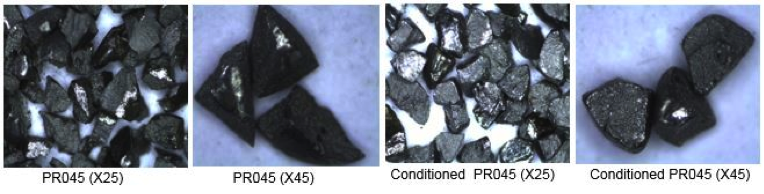

PR045 was improved throughout special treatment and testing process

Step 1. Technical meeting with team of the painting research center to decide the proper abrasive for Yamal project.

Step 02. Demonstration on the Pro45 on the small machine in the research center.

Step 03. Outdoor trials on blocks in order to gain the best working condition (roughness, cleanness and no sticking problem).

Step 04. Finally, a success story was made based on our strong blasting technology and issues were solved through hard efforts and good relationship with the customer.

The customer is confident in the sales and technical teams’ ability to find the right solution to their ambitious projects.

In September 2016 Daewoo Shipbuilding (DSME) delivered 3 vessels for Icebreakers Yamal project. SSK expects an increase in sales volume for the remaining 12 vessels

Contact: Dae-Hyun.KIM@wabrasives.com