The ultimate solution to obtain a precise and reliable conductivity measure

Why to pay attention to Conductivity features?

Conductivity is crucial for our clients who prepare metallic surfaces and other shot-blasted surfaces requiring a protective coating.

The ions deposited on the surfaces during the shot-blasting process can lead to increased corrosion. Monitoring salt contamination with various types of tools and techniques allows for precise measurement of this value.

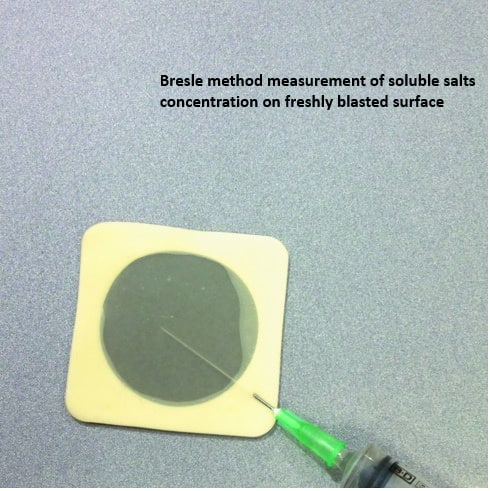

The Bresle method

Several tools available for monitoring salt concentrations:

Measurement methods and relevant tools

The Bresle method uses a patch and syringe to analyze the concentration of salts, expressed in mg/m², in accordance with ISO 8502-6 and ISO 8502-9 standards.

For more details:

This first Salt Meter Method tool, known as the Bresle method, measures the concentration of salts in solution and is expressed in mg/m² according to ISO 8502-6 and ISO 8502-9 standards. The test involves injecting a small volume of distilled water (approximately 3 ml) using a syringe through a protective patch approximately 35 mm in size, attached to the metal surface being inspected. After a waiting period of about 10 minutes, the liquid, which is assumed to be charged with salts, is analyzed using the Salt Meter Method device. In the pipe coating industry, the ISO 21809 standard applied to this sector requires a value of < 20 mg/m².

The Hédon Conductimeter (SSM)

The Hédon Conductimeter (SSM) compares the reference deionized solution with the analyzed surface to measure the presence of soluble salts, expressed in millisiemens (mS/cm) or converted to mg/m².

This second Salt Meter Method device, called Hédon Conductimeter (or SSM for Soluble Salt Meter), measures the presence of salts on shot-blasted surfaces through a reference deionized solution (distilled water or a well-defined concentration) by comparing it with the current situation of the chosen area.

Soluble salts will be expressed in millisiemens (mS/cm) or converted to mg/m² according to the required value unit. The major advantage of this Salt Meter Method SSM device is its practicality, as it is magnetic and easily attaches to all flat surfaces, even those oriented vertically. The liquid is injected into the compartment through a conduit connected to a small reservoir containing the solution.

An automatic impulse piston creates agitation to mix the solution well and maximize the representativeness of the test. At the end of the cycle and the stopping of the piston’s pacing, the measured values appear directly on the screen, and it is enough to select the relevant values of interest.

Applications

Ensure the longevity and quality of your surfaces by investing in a salt test kit for surface preparation. Order yours today and eliminate uncertainties related to surface preparation!

Conductivity meters are perfect for use in sectors such as:

How to prevent from salt contamination and reduce the conductivity?

Metallic surfaces can be contaminated by various environmental factors. To minimize this contamination, it is recommended to use an abrasive that transfers few free ions during shot blasting.

According to the ASTM D4940 standard, an abrasive with conductivity less than or equal to 50 µS/cm has a low level of contamination. The final cleanliness of the parts after shot blasting also plays an essential role in slowing down corrosion.

It should be noted that W Abrasives’ steel abrasives have a conductivity lower than 50µS/cm…