Introducing Rehan Ahmad and the Winoa India plant

Question: Can you introduce yourself and describe your site?

Rehan Ahmad: My name is Rehan Ahmad, and I am the QA and Health & Safety Manager at Winoa-2Effe Private Limited in Pune, India. I joined Winoa as a Quality Manager, bringing over 17 years of experience from the automotive and locomotive metro industries. I have led sigma projects focusing on quality as well as health and safety initiatives in both sectors.

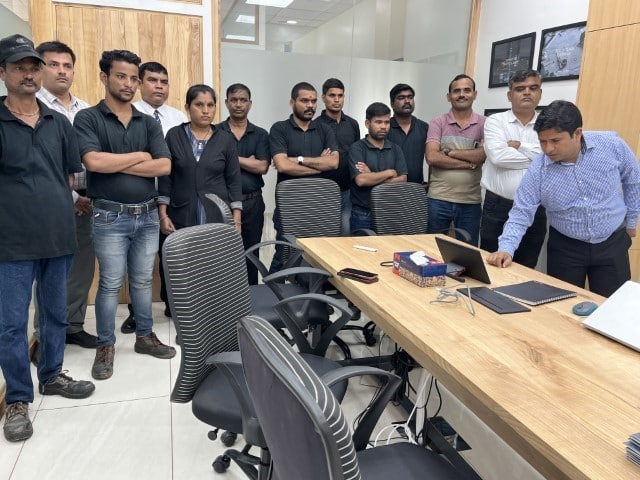

At our Indian facilities, we operate two separate entities: Winoa Abrasive India, which has been running for over 12 years, and Winoa-2Effe, a new joint venture between Winoa France and 2EFFE Engineering Italy. Health and safety is our top priority. From September 9th to 13th, 2024, we organized a Health & Safety Week at the site. The event featured activities like H&S awareness training, a fire extinguisher drill, a quiz competition, as well as sports and yoga activities to promote safe practices across the team.

“Health and safety of our employees is our first priority.”

Health and Safety Challenges at Winoa India

Question: What are the specific health and safety challenges of your site, and how do you manage them?

Rehan Ahmad: One of the main challenges we face on our new site is ensuring that all employees, especially new ones, fully understand the H&S rules. Another key challenge is managing the safety of external contractors who work on machinery during commissioning or repair. Since many people on-site are external workers, ensuring consistent enforcement of H&S policies can be complex.

To address these challenges, we have put in place strong measures to ensure that our health and safety rules are well understood and strictly applied across all areas of the plant. Continuous communication and regular training are critical to reinforcing this culture.

Recent Safety Improvements and Their Results

Question: Can you share a recent situation where a safety improvement was made at your site? What were the results?

Rehan Ahmad: At Winoa-2Effe, we recently implemented a Health & Safety Walk as part of our continuous improvement process. During these walks, we identify unsafe conditions and work on immediate corrective actions.

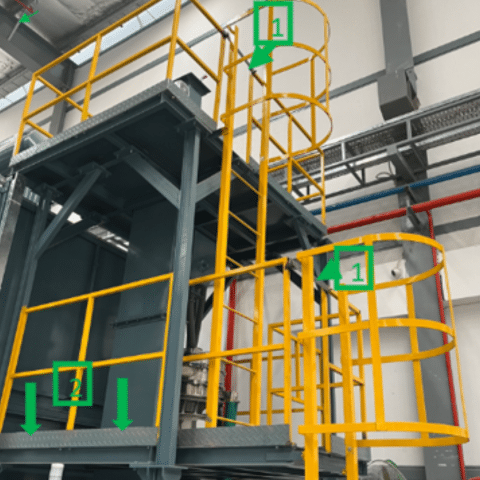

One specific improvement involved adding safety guards to a newly installed machine to prevent accidents. Before the addition of the safety guard, there was a risk of falls due to unprotected areas. We addressed this by installing proper safety barriers on the machine platform, effectively eliminating the risk. Since this improvement, we have recorded zero safety incidents in the plant.

Photo caption:

- Safety guard added to prevent falls.

- Safety guard wall installed on the platform to prevent foot slippage.

“The effectiveness of continuous improvement in H&S is reflected in our record of ZERO safety incidents.”

If you work with machinery, safety is essential. Download our free guide, “Best practices for safe machine operations,” to ensure your team is protected and reduce risks at your site.

Applying Safety Principles in Daily Life

Question: Which safety rule or good practice that you follow at work do you also use in your daily life?

Rehan Ahmad: The main safety principle I follow both at work and in my personal life is “Think Safety First.” I believe safety should be the first consideration before taking any action. This mindset has changed the way I approach daily tasks, even at home.

For instance, before adopting this mindset, I had never considered having a first-aid kit at home. Now, after reflecting on the importance of safety, I have purchased a first-aid kit for my household. This small action ensures that I am prepared for any minor accidents that may occur at home, just as we prepare for emergencies at work.

Thank you, Rehan Ahmad, for taking the time to share your experience and thoughts on health and safety. We appreciate your dedication to keeping our workplace safe, and we hope this interview highlights the key role safety plays at Winoa.