Non-Ferrous metal surface preparation: The benefits of Stelux™ CG abrasive

How can you improve your surface preparation process while avoiding ferrous contamination? Your technical solution may be found in the range of Stelux stainless steel abrasives, particularly Stelux™ CG. This is a dedicated stainless steel shot for surface preparation and deburring of stainless steel, aluminum, and non-ferrous parts

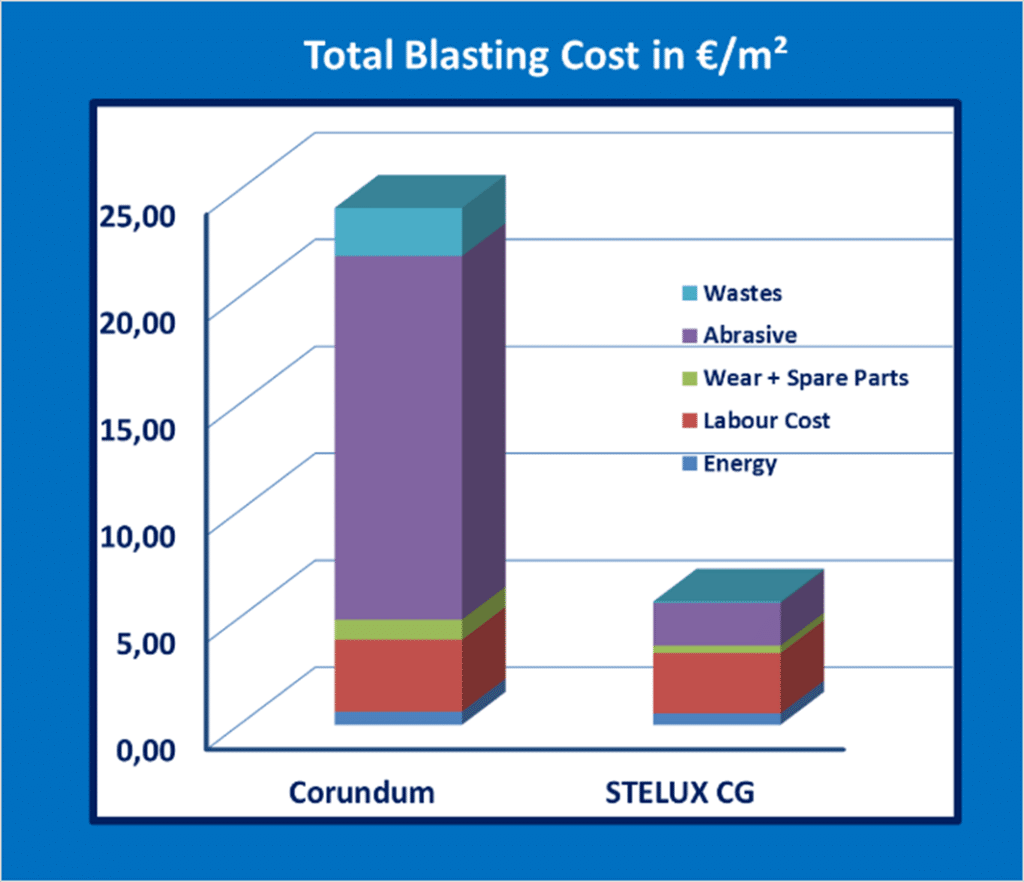

Stelux™ CG has emerged as a high-performing and cost-effective solution, reducing abrasive consumption by 10 to 20 times compared to non-metallic shots like aluminum oxide (or corundum). Moreover, it allows industries to save more than 50% on their abrasive, equipment maintenance, and waste treatment costs.

To back this up, we have conducted several comparisons, the results of which we present to you.

Comparison of abrasive consumption : 3 kg/h

STELUX CG 20 vs. 30 kg/h white F46 corundum

What are the advantages of using Stelux™ CG Stainless Steel Abrasive?

key advantages of the SteluxTM CG abrasive

Thanks to its extended lifespan and ease of recycling, the SteluxTM CG abrasive provides a genuine eco-friendly alternative when compared to other cleaning products such as garnet or aluminum oxide sandblasting, as well as other mineral abrasives. These alternatives have the significant drawback of generating more waste and dust emissions or requiring chemical operations like acid stripping.

Among the key advantages of the SteluxTM CG abrasive, we can highlight :

Productivity gains for non-ferrous surfaces

Stelux TM CG

Stelux™ CG is a premium-quality stainless steel abrasive for surface preparation, cleaning, and deburring of non-ferrous metals, cast and forged stainless steel parts. It offers a drastic productivity advantage by reducing blasting time.

Why? Thanks to its higher density, which delivers more energy per impact compared to traditional abrasives.

Stelux™ CG is a premium range perfectly suited for surface preparation operations using compressed air blasting.

Proven effectiveness on multiple surfaces:

- Cast, forged, and welded stainless steel parts

- Galvanized steel

- Special alloys: Nickel-based alloys, titanium

- Aluminum cast alloys and parts

- Non-ferrous metal castings and parts

- Pressure-cast zinc parts

Cost Savings: Less maintenance, less consumption, less waste

performance & recyclability

The performance and recyclability of Stelux™ CG stainless steel abrasive help our clients save on operational costs and reduce waste overall, compared to other non-metallic abrasives like garnet, aluminum oxide, and silica sand.

Total blasting costs are significantly reduced thanks to optimized maintenance (replacement parts, flexible hoses, nozzle equipment), resulting in savings of 50 to 70%.

With a reusability rate ranging from 40 to 100 times greater compared to other abrasives like sand, slag, and garnet, Stelux™ CG is the solution for achieving a 100% recycled material goal. This is possible due to the monetary value of the emitted dust, which is composed of stainless steel and can be reused in various other applications, unlike traditional non-metallic abrasives that end up as waste.

SteluxTM CG : comparison and key numbers

| Main Products Characteristics and Cost Comparisons | STELUX CG | AlOx | Garnet | Glass Beads |

| Hardness (HV – Vickers) | 650 HV | 2000 HV | 1450 HV | 440 HV |

| Density (Specific Gravity) | 7.4 SG | 3.9 SG | 3.9 SG | 2.5 SG |

| Shape | Angular | Angular | Sub Angular | Rounded |

| Profile | +++++ | +++ | ++ | + |

| Average Consumption for a Sa 2 ½ surface aspect grade | 0.5 kg/m² | 18.75 kg/m² | 30 kg/m² | 30 kg/m² |

| Average Waste Generation | 0.4 kg/m² | 15 kg/m² | 23 kg/m² | 23 kg/m² |

| Price / Ton | €€€€ | €€€ | € | €€ |

| Abrasive cost €/m² | 2.06 €/m² | 19 €/m² | 14 €/m² | 19.55 €/m² |

STELUX CG VS. MINERAL ABRASIVES

SteluxTM CG technical data sheet

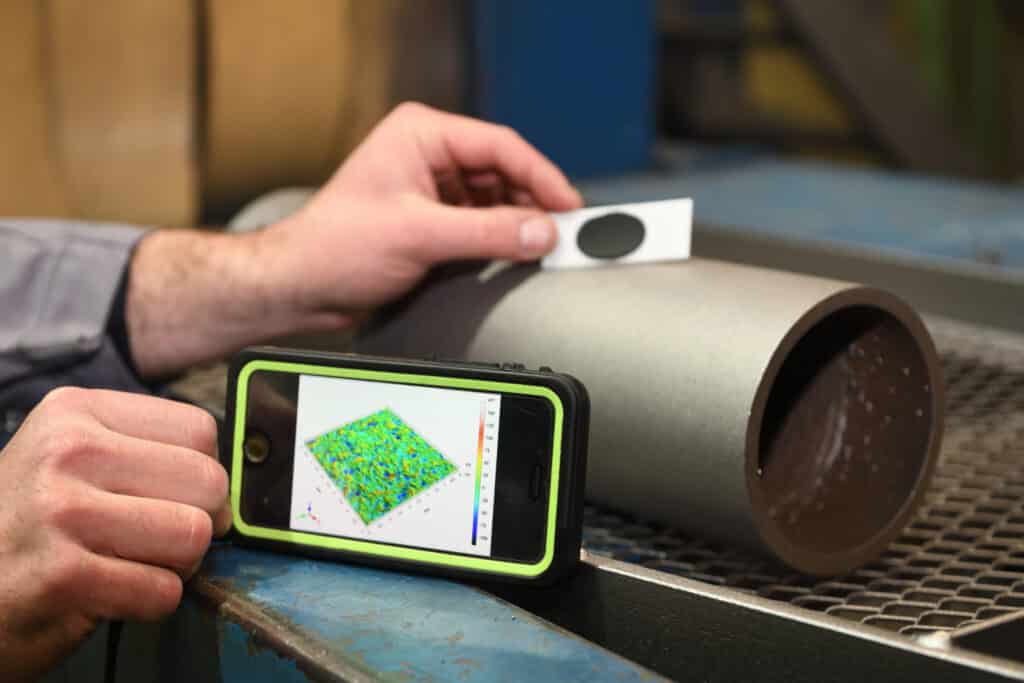

Formation, technical assistance, tests, and customer trials

In our Winoa test centers, strategically located around the world, we offer advanced testing possibilities. These state-of-the-art facilities are equipped with the latest technologies and are designed to meet the highest technical requirements. We provide a controlled and secure environment to conduct tests in various fields, such as electronics, automotive, aerospace, and many more.

Our technical support teams are available to provide ongoing assistance to our customers. Whether it’s to answer technical questions, solve issues, or offer expert advice, we work closely with you to understand your goals, analyze your specific needs, and provide you with valuable recommendations.

W Abrasives provides customized solutions for your application through products, technologies, and specific services that will enhance your surface preparation process.

Whether you need to optimize your test processes, solve complex issues, or improve your performance, our consulting team is here to help you achieve your goals.