ABRASIVE MEDIA FOR Steel SHOT BLASTING

Steel abrasives media

Optimizing costs with the right abrasives

We have been an industry innovator in steel abrasives for over 60 years.

Steel shot blasting operations require shot abrasives of specific properties, with different levels of hardness and resistance over time. Especially since our steel abrasives are fully recyclable, reusable several thousands of times!

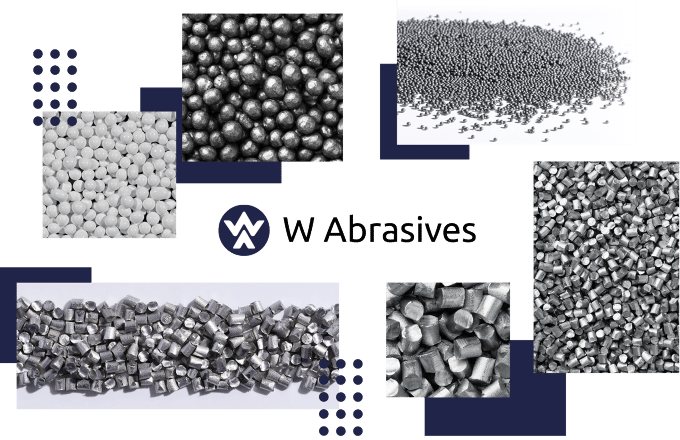

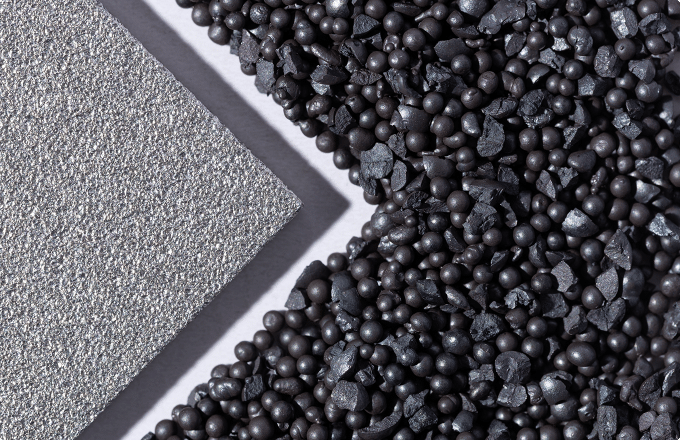

Our innovative products are available in different shapes: shot, grit, angular and mix.

Our main objective is to provide our customers with the right steel abrasives for the operations they need to carry out, in complete reliability, and at the same time optimize their costs.

Our different types of steel blasting media

Discover our abrasives range

Steel shot blasting in all its technicity

Steel abrasives

Because markets such as automotive, construction or shipyards meet specific challenges, the characteristics of our shot abrasive must be adapted to all the features of our customers.This is what we call “the WINOA touch” which makes all the difference in steel shot blasting!

Why choose steel abrasives ?

Advantages of metallic medias

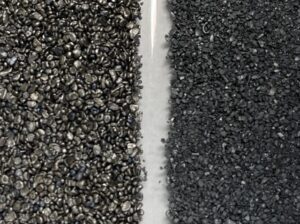

Steel shot abrasives are made up of spherical particles, while steel grit abrasives consist of crushed shot, producing angular and irregularly shaped particles. They can be used to remove unwanted materials such as rust, paint and scale from the surface of a part, to produce a certain texture on the surface of a part, or to harden the surface.

Low cost of use:

- The cost of using steel shot is relatively low, compared to other shot blast products.

Respect for the environment:

- Being 100% recyclable – and reusable thousands of times – they are a safe choice for everyone

High performance:

- Steel blasting media are efficient, and optimize energy consumption. They enable faster cleaning and surface preparation than with other media.

Steel Abrasives in Numbers

Advantages of steel medias

+100x Reusable

Shots and grits are reusable up to thousands of time. Even with the less effective cleaning system, you’ll save enormous volumes of media vs expandable abrasives.

99% Waste reduction

By using recyclable cast steel abrasives, you drastically reduce your waste, having a positive environmental impact and significant disposal cost reductions!

+15% Productivity

Steel abrasive have a greater mass than mineral media (Garnet, Alu. Oxide, etc), thus releasing more energy, which increases the speed and productivity of shot blasting.

-50% Production costs

Reduced consumption, increased productivity and reduced disposal costs= increase profits!

Focus on quality

Quality control in our steel abrasives

The conformity of our steel abrasives is our commitment, at the side of our customers.

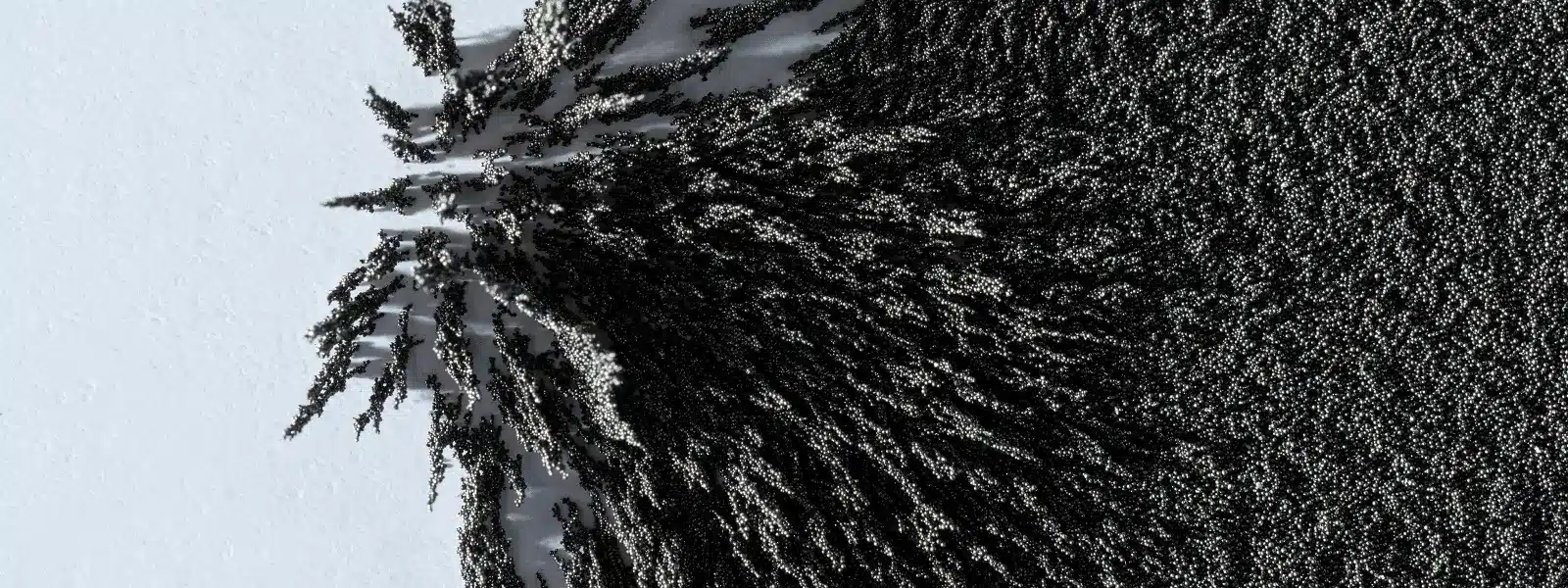

Density, voids and shape control

We use a variety of physical factors, samples are tested 3 times a day.

Microstructure anomalies

Heat treatment and quenching generate fewer cracks and superior microstructure.

Final shot

Hardness in the 47-48 HRC range provides the best compromise between cleaning efficiency and durability.

Why choose our steel abrasives?

Security and performance

By listening to our customers, we develop different ranges of steel blasting products. Each range corresponds to specific uses and is associated with a range of services to meet each industrial challenge.Preparing your steel shot blasting operations with us mean choosing security and performance!

Did you know?

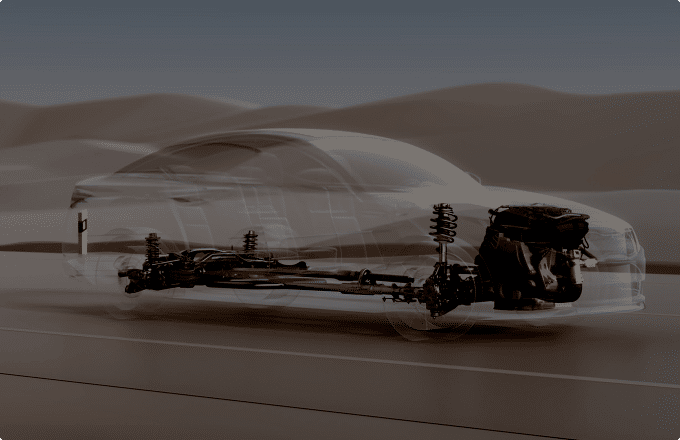

Interesting facts about steel shot in automotive manufacturing

Did you know that an average of 3.7 kg of shot is used to manufacture the various parts of a motor vehicle?

The shot contributes, among other things, to aesthetics by preparing surfaces for painting, increasing the life cycle of the various springs by peening, or cleaning cast iron parts such as transmissions before machining!