Surface Profile Technologies & Solutions

Why to focus on roughness surface profile?

Surface profile

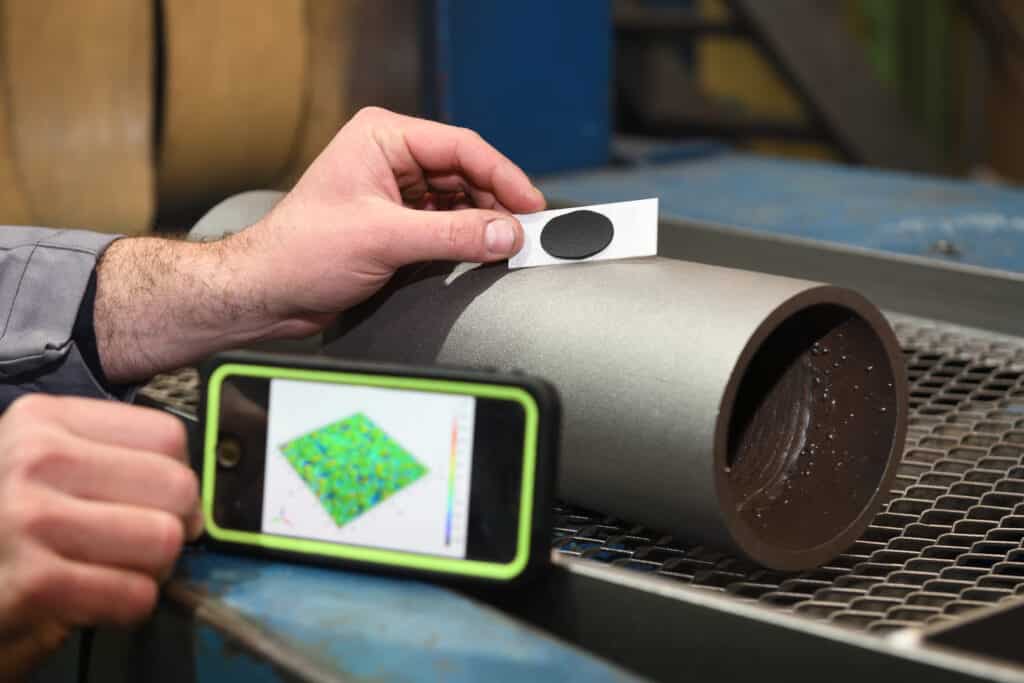

A large portion of our clients have a so-called “surface preparation” or surface Profile orientation on metallic parts. This application is intentionally aimed at creating a rough appearance. The asperities of the Profile are artificially created to increase the contact surface between the metal and the coating. The surface profile can be more or less pronounced depending on the applied coating and adhesion requirements.

The shape and uniformity of the roughness profile will depend on various choices and several adjustment elements. Our W Care experts can also assist you in these investigations to achieve your predefined objectives as closely as possible. Discover our range of tools and technologies here!

Discover our available tools and technologies

How to reach to closest determined roughness surface profile?

The roughness surface profile

In order to determine the best combination between the choice of abrasive, its size, and the ideal projection speed for your surface profile objective on your parts, our Tech Centers are a first step among our service offerings. The homogeneity of the roughness profile is subsequently better stabilized in the case of a well-managed operational mix. Our W Care experts take care of the complete training of your teams and the support assistance on your machines.

Why to improve surface roughness profile?

IMPROVEMENT OF SURFACE ROUGHNESS PROFILE

Nowadays, paint coating products or other protections have evolved significantly. Due to their chemical components, their texture, and the application method, it is possible that your surface Profile requirements may need to be reviewed. Moreover, some uses of the finished products require a very long-term adhesion of the coatings (some guarantees require a minimum of 30 years for pipelines). The surface Profile must be particularly precise to both minimize the use of the protective layer and prevent the initiation of corrosion points.

Our service offerings are therefore the faithful allies in the optimization of your workshop machines and the control of your production costs.

Measurement methods and relevant tools to check your surface profile :

Surface Profile Optimization

Our teams of Experts will start by determining the projection speed of the abrasive. Investigations also focus on a granulometric analysis of the used media and the ability to stabilize it in order to make the surface Profile homogeneous over time.

Following this initial expertise, a debriefing is organized face-to-face and our W Care experts are at your disposal to detail our observations. A detailed technical report is transmitted after each mission indicating our recommendations for optimizing the surface Profile.

You are free to retain our offer and validate our surface Profile optimization program.

At the start of operations, our W Care experts will be back on your site in order to carry out, in collaboration with your maintenance and production workshop services, the action plan defined to meet your requirements.

In order to reach these objectives, we implement the following tools and services:

- Determination of the granulometric analysis of the operating mix

- Viewing the grain aspect with the magnifying glass

- Control of the roughness of the surface Profile before launching the action plan, then following the project objective choice.

- Perthometer device implemented which allows to precisely determine the targeted characteristics such as the values of Ra; Rz; Rmax the number Pc, according to the predefined value of Cut-off

- Training of your production and maintenance teams in order to understand the proper functioning of the machine and maintain the correct settings.

Furthermore, the surface Profile measurement service is not limited to a single mission, but will be subject to regular follow-up, thanks to our W Care teams, field and application experts.

References

3D topography for surface preparation applications