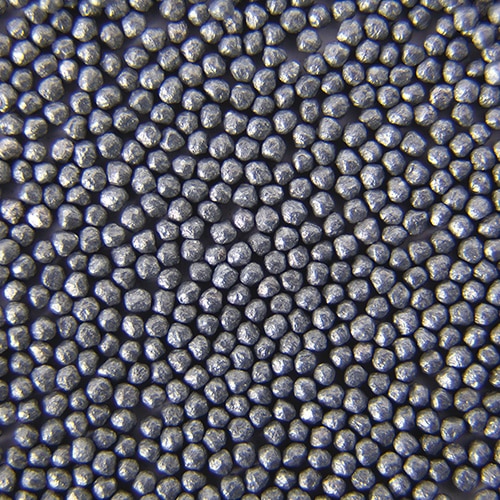

Aluminum Cut Wire

The Versatile Solution for Delicate Surface Preparation

Aluminum Cut Wire is a non-sparking, lightweight abrasive ideal for delicate surface preparation tasks. Its unique properties make it the preferred choice in various industries, ensuring both safety and efficiency.

Features and Benefits:

Features and Benefits:

Maximize Your Efficiency with Aluminum Cut Wire

Aluminum Cut Wire is a non-sparking, lightweight abrasive that enhances operational efficiency by reducing equipment wear and ensuring easy handling. It effectively removes contaminants without damaging delicate substrates, making it ideal for precision applications. Its soft nature minimizes substrate wear, while its recyclability offers an environmentally friendly solution, reducing waste and costs.

Non-Sparking

Lightweight

Soft

Performances

Performances

The Ultimate Choice for delicate surfaces

Non-Sparking Properties

Aluminum Cut Wire is non-sparking, ensuring safety in explosive atmospheres. Its non-ferrous nature makes it an ideal choice for environments where preventing accidental ignitions is crucial, enhancing operational safety and compliance.

Lightweight and Efficient

The lightweight nature of Aluminum Cut Wire reduces equipment wear and tear, making it easier to handle and operate. This efficiency translates into lower operational costs and improved ease of use, making it a preferred choice for various industrial applications.

Superior for delicate parts

Aluminum Cut Wire effectively removes surface contaminants without damaging the substrate. Its soft abrasive properties are perfect for delicate parts, ensuring a clean and smooth finish ideal for applications in the aerospace, electronics, and automotive industries.

Reduced Media Consumption

One of the key benefits of Aluminum Cut Wire is its recyclability. It can be reused multiple times, significantly reducing waste and costs. This environmentally friendly attribute makes it a sustainable option for surface preparation, aligning with green manufacturing practices.

Key Advantages

Key Advantages

Aluminum Cut Wire

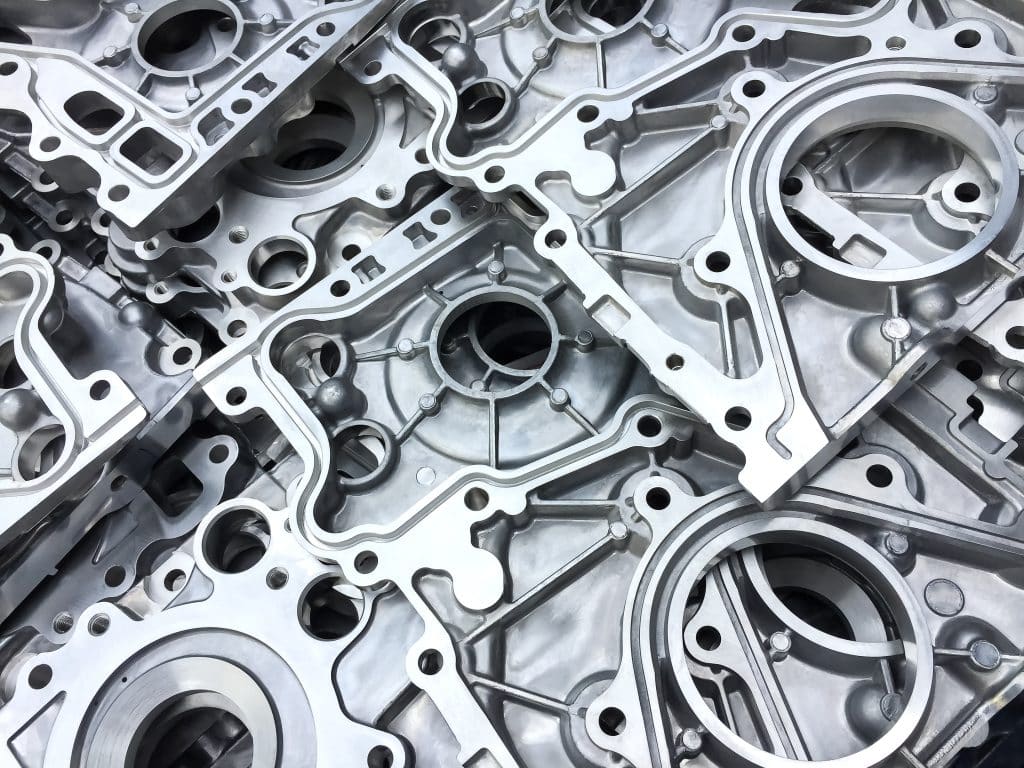

- Electro-chemically neutral: Our Aluminum Cut Wire is electro-chemically neutral on aluminum and magnesium alloys, effectively preventing white corrosion and ensuring the integrity of your components.

- Safe residues: Unlike steel shots, the residues from our Aluminum Cut Wire will not cause damage or fractures to milling, drilling, or threading tools, providing a safer working environment.

- Minimized deformation: Experience less deformation during the blasting process, especially on thin-walled castings. This is crucial for parts with cooling fins that are prone to deflection.

- Cost efficiency: Reduce maintenance costs and downtime with our Aluminum Cut Wire, which exhibits minimal wear on blasting spare parts, leading to a longer lifespan and lower operational costs.

- Reduced dust emission: Our product generates less dust during blasting, contributing to a cleaner workspace and improved air quality.

Markets and applications

Markets and applications

Industry-Specific Uses for Optimal Performance

Aluminum Cut Wire is perfect for the aerospace industry, cleaning and finishing delicate aircraft components without causing damage. In the electronics sector, it ensures gentle and precise cleaning of parts, maintaining their integrity. For the automotive industry, it is suitable for surface preparation and finishing of parts, enhancing their durability and performance.

Aerospace

Automotive

Electronics

Conditioning levels

Conditioning levels

Aluminum Cut Wire is available in as-cut and one conditioning level to suit your application and performance requirements. These ensure the abrasive media meets specific standards for shape, size, and hardness. Here are the typical conditioning levels for our Aluminum Cut Wire:

As-Cut (Z)

- Description: This is the initial form of Aluminum Cut Wire, cut to precise lengths with sharp edges.

- Applications: Suitable for applications where “aggressive” cleaning is required, providing impact energy due to its sharp edges.

Conditioned / Rounded (G)

- Description: G conditioned cut wire undergoes a rounding process, which smoothens the sharp edges, resulting in a more uniform and durable abrasive.

- Applications: Ideal for applications requiring a more consistent and gentle abrasive action, such as delicate surface finishing and peening where surface integrity is critical.

Technical Specifications

Technical Specifications

for Precision and Quality

Below you will find the range available as standard of our typical aluminum Cut Wire. Other dimensions, hardness, and specifications available on request.

Typical specifications:

Alloy Composition: made from copper-free alloys, specifically AW6060 and AW5056. The absence of copper is essential for preventing galvanic reactions, particularly in applications involving aluminum parts.

Hardness: Typically ranges from 40-50 HRB, offering versatility for different applications.

Sizes: Available in various diameters to meet specific requirements, typ: 0.6 to 1.2 mm.

Packaging Options: Offered in 25 kg bags as standard, 12 kg bags, 30-gallon and 55-gallon steel drums available on request.

| Parameter | Specification |

|---|---|

| Material Composition | 99% High-Purity Aluminum

2 standard alloys avail: AW5056 (harder) and AW6060 (softer)*

|

| Hardness | 40 – 70 HRB |

| Grain Shape | Cylindrical with sharp edges (Z) or Rounded / Conditionned (G) |

| Sizes Available | 0.6 mm, 0.8 mm, 0.9 mm, 1.0 mm, 1.2 mm* |

| Bulk Density | 100 lbs/ft³ / 1600 kg/m³ |

| Tensile Intensity | 80 – 240 MPa |

| Microstructure | Deformed α |

| Density | 2.7 g/cm³ |

| Packaging Options | 25 lb (12 Kg) bags, 30-gallon corrugated drum, 55-gallon steel drum |

| Applications | Surface improvement, blast cleaning, deburring, delashing |

| Compatible Equipment | Air blast |

| Recyclability | Can be reused multiple times |

These specifications offer an overview of the available properties and potential applications.

*Other sizes, alloys, conditioning levels, and packaging options are available upon request.

You may also like

You may also like

Other great blasting solutions

Technical Frequently Asked Questions (FAQ)

Technical Frequently Asked Questions (FAQ)

Aluminum Cut Wire

Yes, Aluminum Cut Wire is compatible with both air blast and wheel blast equipment. When using in wheel blast machines, adjustments may be necessary to accommodate the lower density of aluminum compared to other metallic abrasives, such as modifying the feed rate and rotational speed to maintain optimal performance.

Aluminum dust could indeed be explosive under certain conditions. Special precautions include using a wet scrubber or similar dust suppression system to minimize airborne dust and static discharge. Ensuring proper ventilation and using explosion-proof equipment can also help mitigate the risks. Handling aluminum cut wire in well-ventilated areas and regularly cleaning dust accumulation are essential practices.

Selecting the appropriate size and shape of Aluminum Cut Wire depends on the specific application requirements. Smaller sizes (e.g., 0.6 mm to 1.0 mm) are preferred for delicate cleaning and fine finishing tasks, providing a smooth and uniform surface. The cylindrical shape with sharp edges enhances the effectiveness of the wire in removing contaminants and achieving the desired surface profile. Considering the specific needs of the application, such as surface roughness and the material being cleaned, is crucial for optimal performance.

The grain shape of Aluminum Cut Wire is controlled during the cutting process, which produces cylindrical grains with sharp edges. In addition, (G) rounded/conditioned cut wire undergoes further conditioning to round off sharp edges, resulting in a more uniform, sharpless and durable abrasive. This process enhances the performance of the wire in abrasive blasting and peening applications by reducing the risk of fractures and improving longevity.

Aluminum Cut Wire is typically manufactured from high-purity aluminum (99% purity) and various aluminum alloys from the 4000, 5000 and 6000 series. These compositions ensure optimal performance in terms of strength, ductility, and corrosion resistance.