Hybrid Shot / Foundry

Premium mix for low machine wear in desanding operations

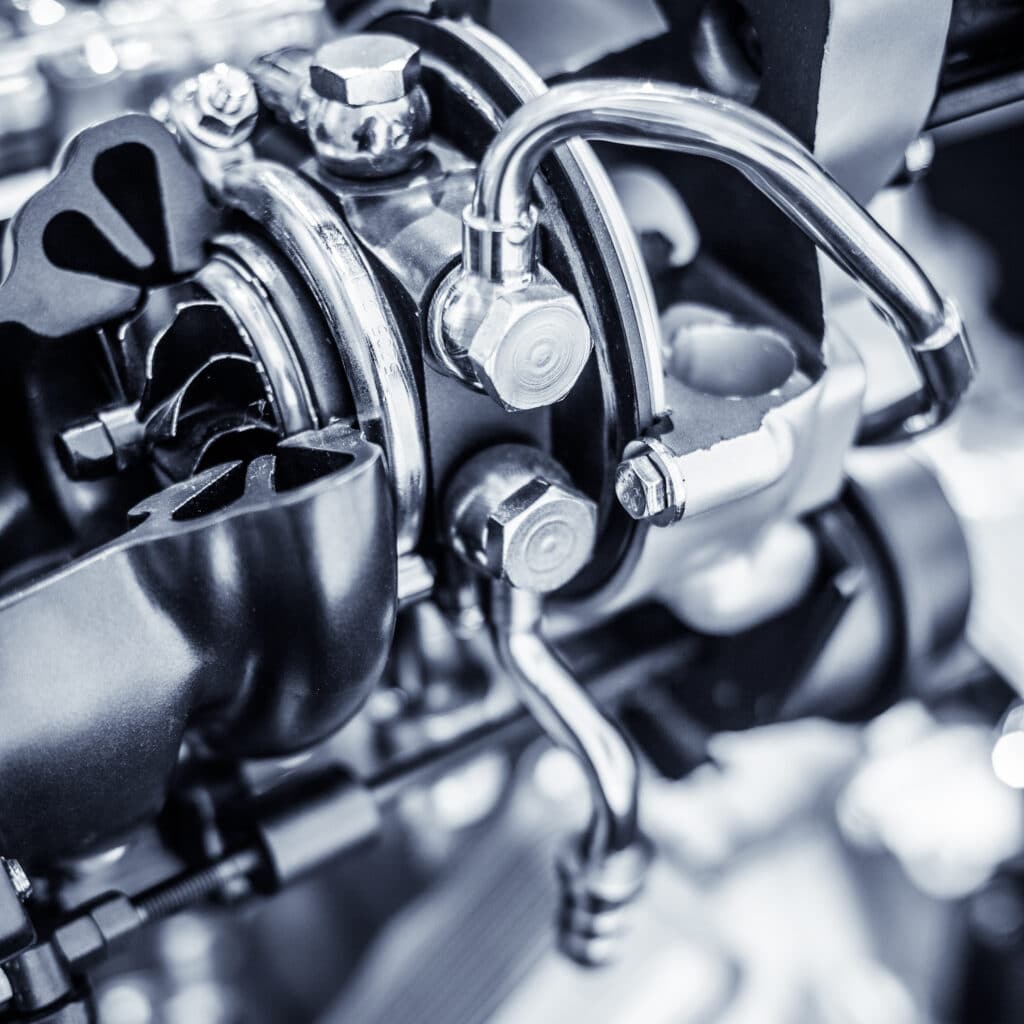

HYBRID SHOT was developed specifically to address new demands for desanding in foundries and descaling in forges and wire drawing plants. By reducing machine wear it helps to reduce maintenance costs while at the same time achieving remarkable performance in terms of cleaning

Users benefits

Users benefits

High rebounding capacity

High efficiency

Improved stability of operating mix

Specific heat treatment

Performances

Performances

#1 Cost & Maintenance Reduction

- Reduced machine wear and parts consumption

- Improved process stability due to longer lasting operating mixing

- Controlled and regular surface profile

#2 Cleaning Performance

- Improved parts cleanliness, including complex shapes

- Increased cleaning efficiency compared to High or Low Carbon steel shot

#3 Consumption

- Longer abrasive life compared to round steel shot

- Reduced power consumption for shot blasting (ISO 14001)

Markets and applications

Markets and applications

Desanding & Descaling

Cast steel & cast iron foundries

Forges

Automotive castings

Equipment goods

Construction castings

Specifications

Specifications

| Product name | HY 020 | HY 040 | HY 050 | HY 060 | HY 080 | HY 100 | HY 120 | HY 140 |

| Nominal size (Sieve #) | 1,7 mm

(#12) |

1,4 mm

(#14) |

1.4 mm (#14) |

1,18 mm

(#16) |

1,00 mm

(#18) |

0,85 mm

(#20) |

0,60 mm

(#30) |

0,425 mm

(#40) |

| Hardness | Specific hardness : 45 – 49 HRC | |||||||

| Density | AbsoluteApparent

≥ 7 g/cm3≥ 4 g/cm3 |

|||||||

| Chemical composition | C ≥ 0.80% , Si ≥ 0.40% , 0.6% ≤ Mn ≤ 1.2% , S ≤ 0.05% , P ≤ 0.05% | |||||||

| Shape | Round and Angular (new), elliptical (operating mix) | |||||||

| Packaging | BOXED BAGS 1000 kg (2,205 lb) 40 bags of 25 kg (55 lb) per palletBIG BAG 1000 kg (2,205 lb)DRUM 1000 kg, 771 kg |

|||||||

Other sizes and specifications available after evaluation. Please contact us for details.

You may also like

You may also like

Premium steel media

This exclusive combination of a Premium Product ensuring better performance than standard products, and a Premium Service to guarantee the optimum use of these products in order to obtain better results in terms of quality and cost, is a pillar of the W Abrasives philosophy.

Case Studies & News

Case Studies & News

Resources & downloads

Resources & downloads