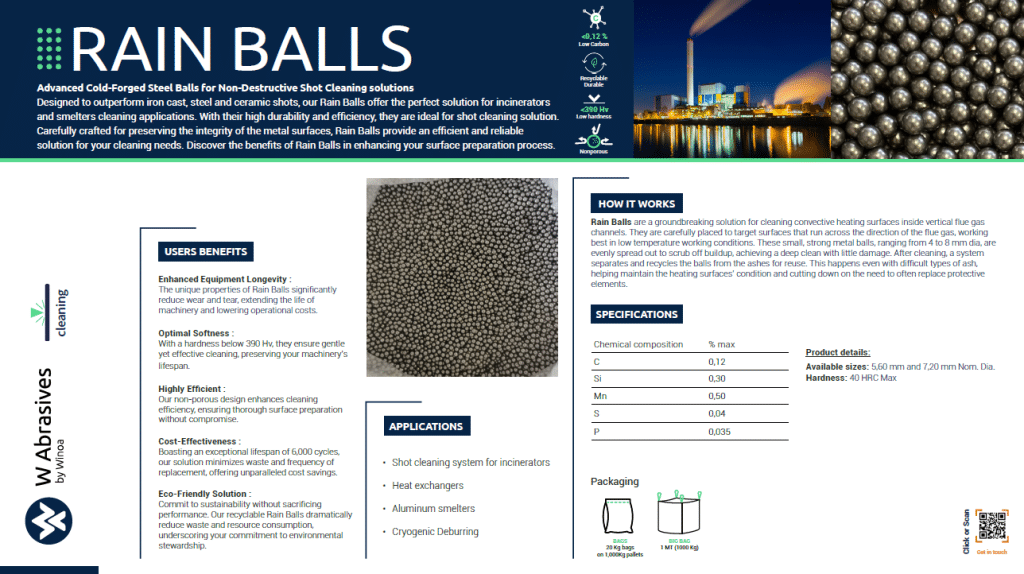

Rain Balls

Eco-friendly, durable, and engineered for performance

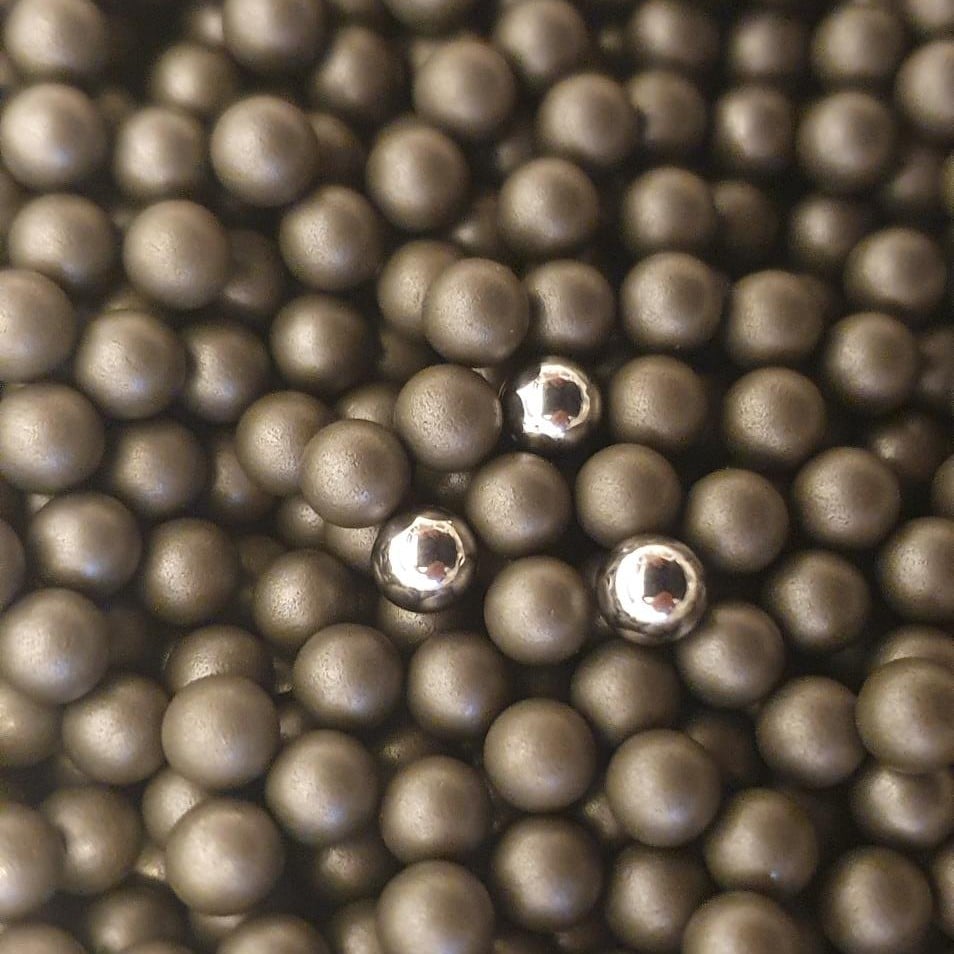

Rain Balls by Winoa are an innovative, eco-friendly cleaning media specifically designed to meet the demands of industrial cleaning applications. These precision-engineered low-carbon steel balls are crafted to provide outstanding performance in challenging environments like waste-to-energy (WTE) plants, heat exchangers, and smelters. Utilizing a straightforward yet highly effective cleaning principle, Rain Balls are propelled by gravity or pneumatic systems to strike and descale surfaces, effectively removing ash, rust, and other deposits from equipment.

This advanced cleaning technology not only restores surface efficiency but also reduces operational downtime, extending the lifespan of critical industrial assets. With exceptional durability—lasting up to 6,000 cleaning cycles—and a hardness below 390 Hv, Rain Balls deliver gentle but powerful cleaning that preserves the integrity of delicate surfaces. Their recyclable nature aligns with modern sustainability goals, making them the perfect choice for environmentally conscious industries seeking cost-effective, high-performance solutions.

Why Rain Balls are the superior choice for shot cleaning systems

Why Rain Balls are the superior choice for shot cleaning systems

Product features and benefits

- Durable and cost-effective

Rain Balls boast an extended lifespan of over 6,000 cycles, reducing drastically the need for frequent replacements and lowering operational costs.

- Eco-friendly and sustainable

Made from low-carbon steel, with a specific hardness for the application, Rain Balls are fully recyclable, minimizing waste and supporting environmentally responsible practices.

- Optimal cleaning performance

With a hardness below 390 Hv, Rain Balls ensure thorough yet gentle cleaning, preserving the integrity of sensitive industrial surfaces.

Versatile cleaning media for industrial environments

Versatile cleaning media for industrial environments

Applications

Rain Balls are engineered to meet the rigorous demands of a variety of industrial cleaning applications, delivering superior results in environments where efficiency and precision are critical. Here’s how Rain Balls are transforming industrial cleaning across key sectors:

- Incinerators and industrial boilers:

Designed for compatibility with various boiler configurations, Rain Balls provide continuous cleaning of convective heating surfaces, ensuring that operational efficiency is maintained even in harsh conditions. - Chemical processing and refineries:

Rain Balls are also applicable in cleaning equipment prone to fouling in chemical processing plants and refineries, improving safety and operational reliability. - Cryogenic deburring:

Rain Balls are ideal for cryogenic deburring applications, where their low hardness and precision-engineered spherical shape allow for the gentle and non-destructive cleaning of intricate parts in industries such as aerospace, automotive, and medical devices. - Waste-to-energy (WTE) plants:

Rain Balls are widely used to clean boiler tubes in WTE facilities, effectively removing ash and deposits that accumulate during waste incineration. This ensures optimal heat transfer and energy efficiency while reducing the need for frequent manual cleaning. - Heat exchangers:

Rain Balls play a crucial role in cleaning fouling deposits from heat exchanger surfaces, enhancing thermal efficiency and extending equipment life. Their gentle cleaning action preserves the integrity of the heat transfer surfaces, even in high-temperature environments. - Smelters:

In metal smelters, Rain Balls efficiently remove scale and residue from internal surfaces, ensuring smooth operation and reducing energy losses caused by fouling. They are particularly effective in aluminum smelters, where precise cleaning is essential to maintaining production quality.

Technical details at a glance

Technical details at a glance

Technical specifications

Rain Balls are meticulously crafted to deliver superior performance in industrial cleaning applications. Below are the detailed specifications that highlight their precision engineering and versatility:

- Available sizes:

Rain Balls are offered in a range of nominal diameters to suit various cleaning applications:- typical sizes used for cleaning: 4.85 mm, 5.60 mm, 6.35 mm, 7.20 mm

- Available sizes: from 0.6 mm to 22 mm

- Material composition:

- Carbon (C): Max 0.12%

- Silicon (Si): Max 0.30%

- Manganese (Mn): Max 0.50%

- Sulfur (S): Max 0.04%

- Phosphorus (P): Max 0.035%.

- Hardness:

Optimized for gentle yet effective cleaning, Rain Balls feature a maximum hardness of 390 Hv. This makes them suitable for delicate surfaces, reducing the risk of damage while maintaining excellent cleaning performance. - Density and weight:

- Bulk density: Approx. 4.00 kg/dm³

- Designed to deliver consistent cleaning impact for various industrial applications.

- Packaging options:

- 20 kg bags for smaller-scale operations or testing purposes.

- 1-ton big bags for large-scale, continuous industrial applications.

Download our Rain Balls technical brochure here

Frequently asked questions

Frequently asked questions

FAQs

They are made from steel – recyclable and reusable 1000ths times, significantly reducing waste.

Rain Balls are ideal for WTE plants, smelters, and industrial cleaning needs.

Yes, Rain Balls are designed for compatibility with most industrial cleaning systems.