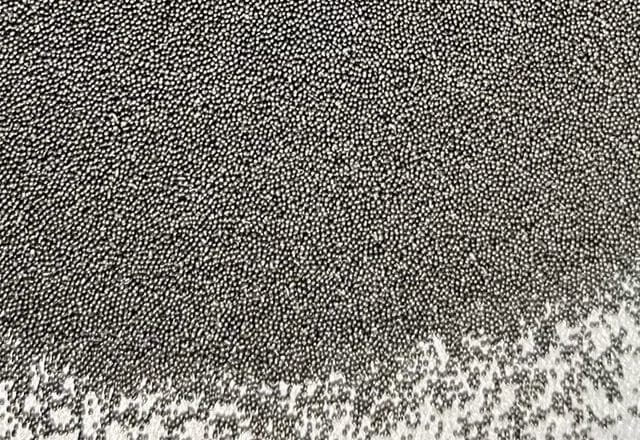

Ultra soft shot

Non-Destructive, gentle and performing cleaning solution.

Designed to replace glass beads, plastic media, zinc shot and soft abrasives in non-destructive blasting and polishing applications, unlike other so-called soft products, Ultra Soft Shot will not work-harden once in use but remains at the same hardness throughout its useful life.

User benefits

User benefits

Recyclable

Heavy density

Low hardness

Applications

Applications

- Deflashing non-ferrous die castings

- Cleaning permanent molds in

aluminium foundries - Removing mold material from

investment casting - Cleaning machined surfaces on steel

or iron - Removing scale from light metal

stampings - Refinishing aluminium automotive

wheels

Specifications

Specifications

| Hardness | <30 HRC (3-5 Mohs) |

| Density | 7.7 g/cc |

| Size available | S70, S110, S170, S230, S280, S330 0.18 mm to 1.18 mm Other sizes available upon request |

How does Ultra Soft Shot compare to other abrasives ?

| Hardness | Durability | Density | |

| Glass Beads | 50-60 HRC (5-7 Mohs) | 5-8 cycles | 2.6 g/cc |

| SAE Steel Shot | 41-65 HRC (6-8 Mohs) | 2500-3500 cycles | 7.3 g/cc |

| Stainless Steel Shot | 20+HRC (work hardens to 45 HRC) | 3500-4500 cycles | 7.0 g/cc |

| Plastic Media | 3-4 Mohs | 4-6 cycles | 1.5 g/cc |

| Ceramic beads | 60-65 HRC (5-7 Mohs) | 300-500 Cycles | 3.5 g/cc |

| Ultra Soft Shot | <30 HRC (3-3.5 Mohs) | 6000-7000 cycles | 7.7 g/cc |