Shot Peening & Finishing

Global Expertise in Shot Peening Services

Surface treatment across industries

At Winoa, we are proud to offer industry-leading shot peening services across our global network of technology centers. Our commitment to excellence in surface treatment is evident in every project we undertake, providing bespoke solutions for a wide range of industrial applications.

Winoa-2Effe: A Specialized Center for Shot Peening Excellence

Combining Expertise with Technology

In addition to our global capabilities, we spotlight our Winoa-2Effe center in Maharashtra, India. This joint venture uniquely focuses on delivering advanced shot peening solutions with the combined expertise of Winoa and 2Effe Engineering.

Key Peening Applications & Processes

WINOA FOR YOUR INDUSTRIES

At the heart of efficiency and product longevity, our peening solutions play a pivotal role across various stages of our clients’ cycles:

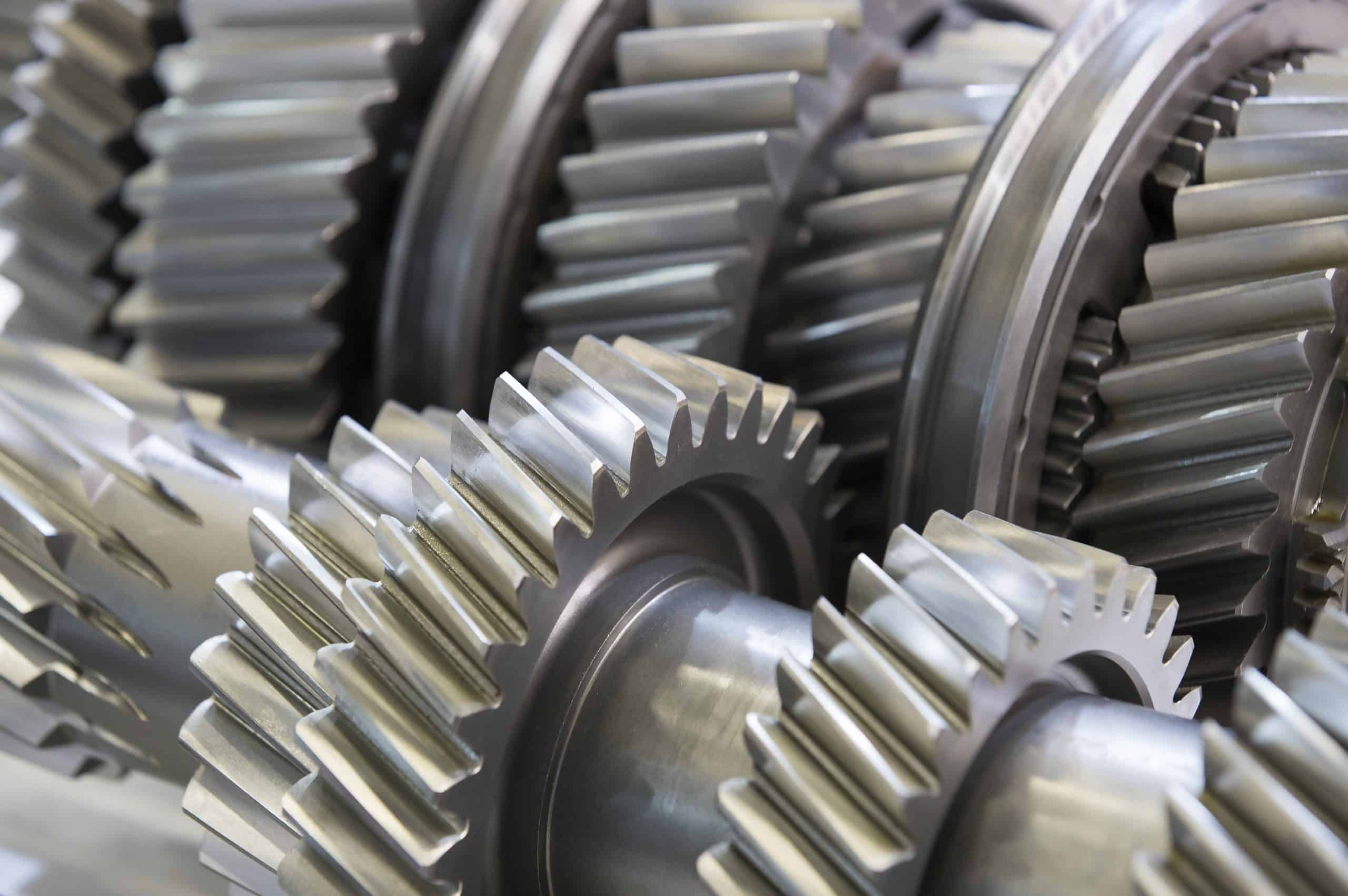

- Enhancing durability of critical components:

Shot peening is used in the automotive, aerospace, and heavy machinery sectors to increase resistance to fatigue, wear, and corrosion. - Innovative applications in medical and technological industries:

Shot peening is applied in the manufacturing of medical implants and technological components, where precision and material strength are crucial. - Stress management:

Shot peening reduces internal stresses in parts, minimizing the risk of cracks and enhancing their durability. - Dimensional precision:

Peen-forming finely adjusts the shape of parts to meet precise tolerance requirements. - Optimization of tools and equipment:

Shot peening is used to improve the durability and lifespan of molds, dies, and other critical components in tool manufacturing. - Surface treatment for structural integrity:

Shot peening strengthens structural elements in construction and infrastructure projects, protecting them from wear and environmental conditions.

Each application of our peening technology service is a testament to our commitment to quality, innovation, and the advancement of industrial standards.

Contact us for your shot peening needs

Get in touch

Whether you’re looking for specialized shot peening services at Winoa-2Effe or elsewhere in our global network, our expert team is ready to assist you. Connect with us to discuss how we can enhance the performance and durability of your components.

Our Shot Peening Capabilities

Peening services

Shot peening is a vital process in enhancing the fatigue strength and lifespan of metal components. Our services are integral to industries such as aerospace, automotive, energy, and more. Here’s what we offer:

Expert Answers to Your Queries

FAQ

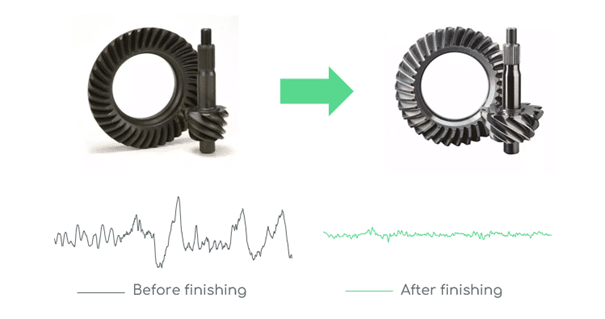

Shot peening is a surface treatment process where small spherical media, known as shot, bombard the surface of a component. This process creates compressive residual stresses, which significantly improve the fatigue life and resistance to stress-corrosion cracking of the component.

Shot peening is versatile and can be applied to a wide range of metals, including steel, aluminum, and titanium. The process parameters are carefully adjusted based on the metal type to ensure optimal results without damaging the component.

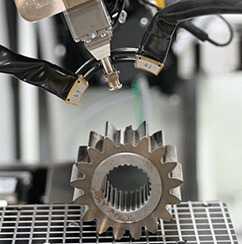

X-ray diffraction is a non-destructive testing method used to measure residual stresses and structural changes in materials. In shot peening, it’s crucial for verifying the effectiveness of the process and ensuring the integrity of the treated components.

Absolutely. Shot peening is widely used in the aerospace and automotive industries to enhance the durability and lifespan of critical components like gears, springs, and turbine blades. But many Industrial applications can benefit from this technology.