The importance of robust surface preparation in Wind Towers

The shift towards renewable energy is accelerating globally, and the wind energy sector is a key player in this transition. Wind towers play a critical role in this sector, requiring robust and dependable surface preparation to withstand harsh environmental conditions. Ensuring proper surface preparation is vital for enhancing the durability and efficiency of these structures, guaranteeing their consistent performance over time. This article examines the main challenges in wind tower surface preparation and presents effective strategies to overcome them.

Primary challenges in Wind Tower surface preparation

Achieving optimal surfaces

Corrosion resistance

Corrosion resistance

- Wind towers are exposed to severe weather conditions that can cause corrosion if surfaces are not properly treated.

- Corrosion weakens structural integrity and shortens the lifespan of the towers.

Surface cleanliness

- High surface cleanliness is essential for coating adhesion.

- Contaminants such as oil, salt, and rust can greatly reduce the effectiveness of protective coatings.

Ideal surface profile

- The texture of the substrate, or surface profile, is critical for coating adhesion.

- An inadequate profile can result in coating failures, while an excessively aggressive profile can be costly and inefficient.

Environmental sustainability

- With increasing environmental awareness, the industry is focusing on sustainable practices.

- This includes the use of recyclable abrasives and minimizing waste during surface preparation.

Technical data insights

Importance of Surface Cleanliness

- According to SSPC standards, visual cleanliness of a steel surface is crucial for coating durability. Poor surface preparation is often the main cause of premature coating failure. These standards require the removal of all visible oil, grease, dust, dirt, mill scale, rust, and other contaminants to achieve the necessary cleanliness levels.

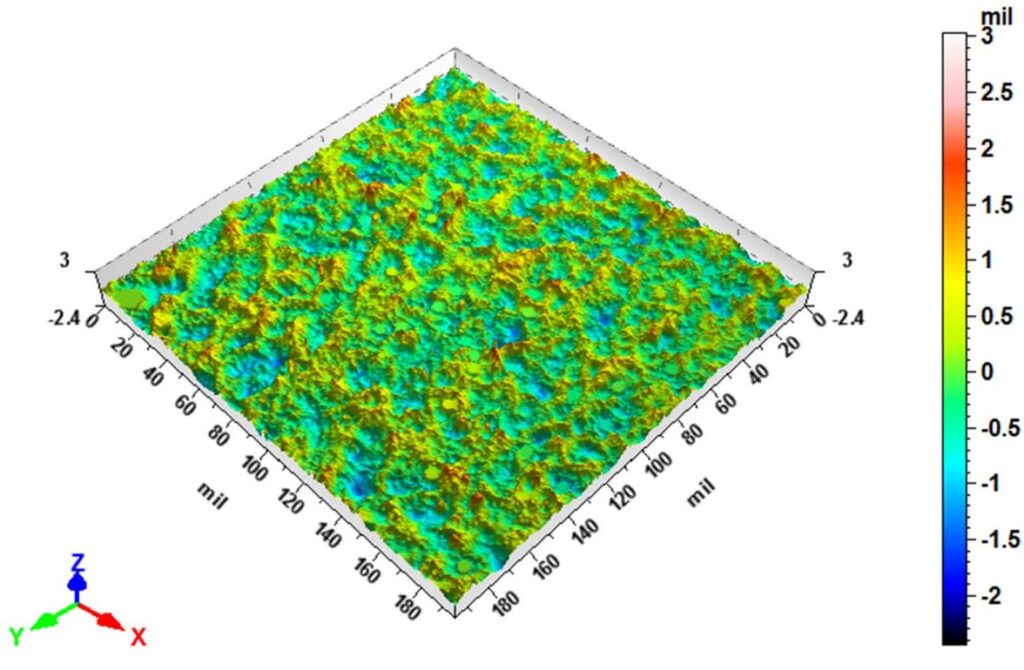

Significance of Surface Profile Depth

- The depth of the surface profile is essential for coating adhesion. For example, an 80-mesh garnet particle can leave a profile depth of up to 3.6 mils on steel. In the U.S., surface profile is measured in mils (thousandths of an inch), with 1 mil equal to 25.4 microns. Ensuring the correct profile depth is vital to prevent coating failures and ensure long-term performance.

Effective solutions for Wind Tower surface preparation

Innovativation & Optimization

Ensuring optimal surface preparation for wind towers is critical for their durability and performance. By leveraging Premium abrasives, optimizing shot blast machines, and employing optimaly testing and measuring tools, the industry can address key challenges and enhance the efficiency of wind tower coatings. Explore these solutions to improve the reliability and lifespan of your wind energy projects.

Premium steel abrasives: Profilium®

Selecting the appropriate shot grit abrasive is crucial for achieving the desired surface profile and cleanliness. W Abrasives’ Profilium® grit abrasives are specially designed for wind tower surface preparation by airblasting, offering several advantages:

- Low Conductivity and Salt Concentration: Minimizes corrosion risk, enhancing the longevity of protective coatings.

- Reusability: Profilium® steel abrasives can be reused multiple times, reducing waste and lowering costs.

- Ideal Profile: Creates a surface profile that enhances coating adhesion with a stable operating mix.

For more information on W Abrasives Profilium media, visit the Profilium product page.

Optimization and Training for shot blast machines

Optimizing the use of shot blast machines can significantly reduce costs and improve the efficiency and consistency of surface preparation. These machines provide precise control over the blasting process, ensuring uniform and consistent surface preparation across all sections of the wind tower. Benefits include:

- Uniformity: Ensures a consistent surface profile, which is crucial for coating performance.

- Efficiency: Reduces preparation time and increases production speeds by up to 40%.

- Cost Savings: Lowers maintenance costs and minimizes material and abrasive waste.

Consult Winoa’s W Care service team to learn how they can help reduce your Total Blasting Costs of Operation.

Surface Preparation solutions

A comprehensive approach to surface preparation involves various tools and instruments designed to address all aspects of the process. Key components include:

- Cleanliness Verification Tools: Devices such as the WA Clean tool measure surface cleanliness to ensure it meets the required standards.

- Surface Profile Effectiveness: Utilizing W Tech 3D Technology to measure skewness and kurtosis parameters (Rsk and Rku) effectively.

- Recycling Systems: Systems for recycling abrasives to reduce waste and operational costs.

Conclusion

Long-Term success in Wind Energy projects

Proper surface preparation is essential for the performance and longevity of wind tower coatings in the renewable energy sector. By addressing challenges such as corrosion resistance, surface cleanliness, ideal profiling, and sustainability, the industry can ensure the success of wind energy projects. Advanced abrasives, shot blast machines, and comprehensive testing and support services are crucial in achieving these goals.

For more detailed information on our surface preparation solutions for wind towers, contact our technical sales team: Contact us now!

Corrosion resistance

Corrosion resistance