Winoa and Canam: Over 20 years of partnership in continuous improvement.

At Canam, a recognized leader in industrial surface preparation, continuous improvement is not just a goal, but a way of working. With over 20 years of collaboration, Canam has turned to Winoa to optimize its processes and reduce blasting times, while navigating linguistic challenges through effective collaboration via Microsoft Teams.

Challenge and Solution

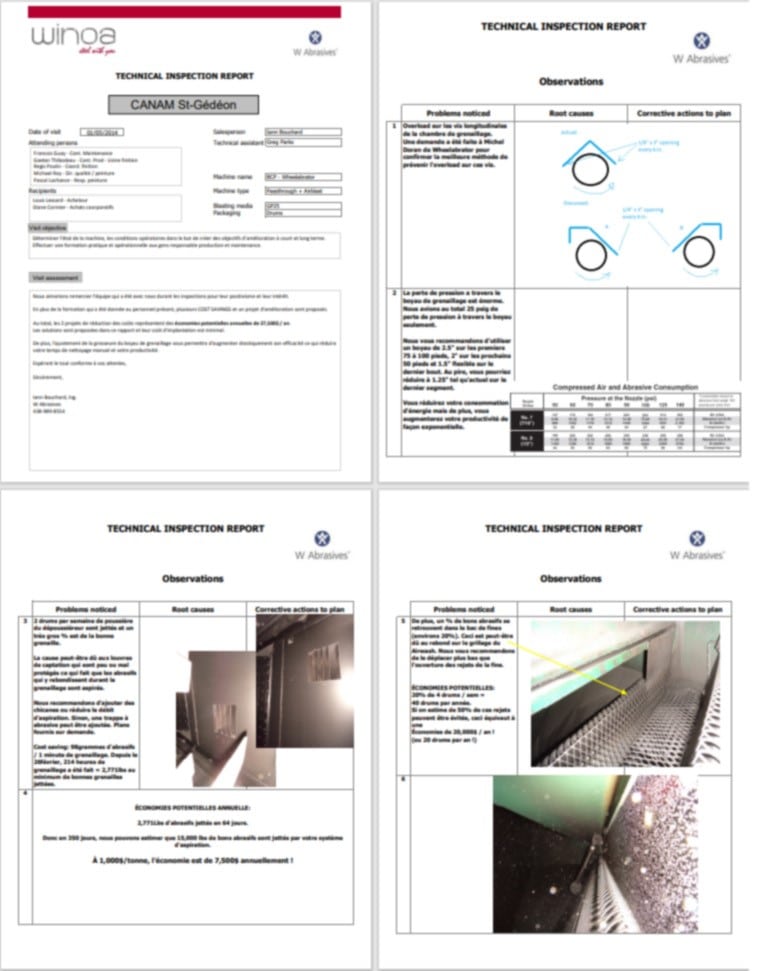

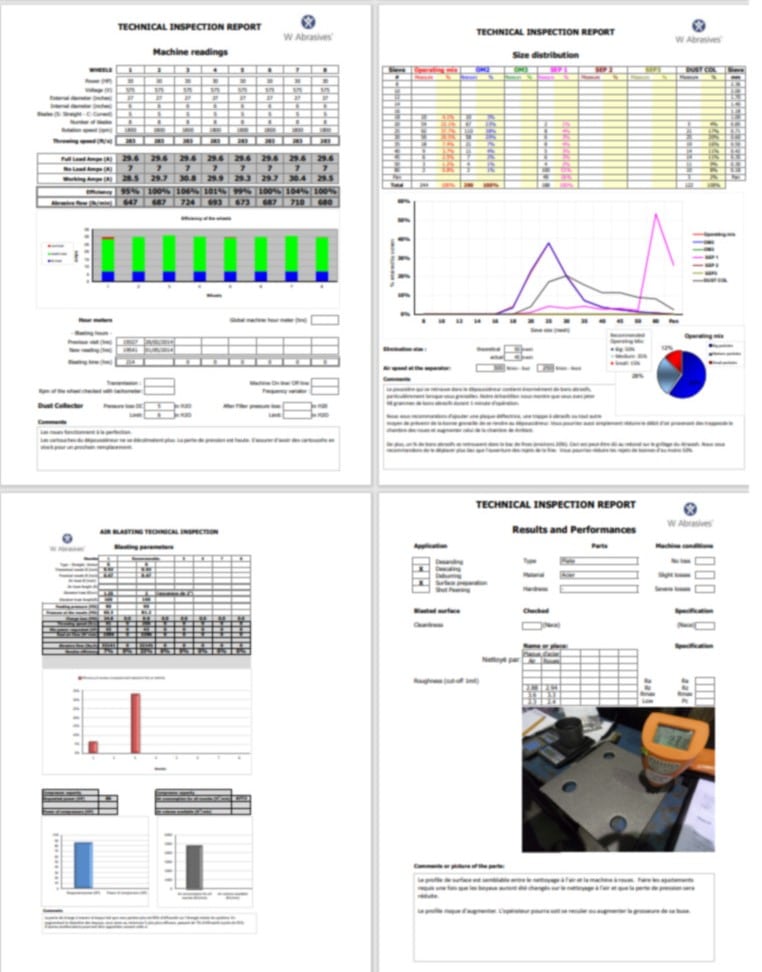

Faced with changes in shotblasting parameters, including the use of new shotblasting wheels and handling a tougher scale on thicker steel parts, Canam faced difficulties with the efficiency of their shotblasting process. The challenge was to understand and measure the impact of these changes on production, especially during winter when cleaning parts becomes more difficult due to the accumulation of snow and ice.

Thanks to an expert team, 22 offices around the world, and approximately twenty technical teams, Winoa responded to this need by providing remote technical support in the client’s local language. These exchanges allowed for in-depth discussions on abrasive selection and shotblasting parameters, the optimization and maintenance of shotblasting machines, the daily monitoring of the system, and the control of operational mixtures and machine parameters. This support was made possible under the WCare program developed by Winoa to advise and accompany our customers remotely or in one of our technical centers.

Impact and Results

The collaboration led to the establishment of a plan for optimization of shotblasting parameters, with ongoing monitoring and adjustments. While the final results are still under evaluation, early feedback following initial modifications is promising, indicating potential for a decrease in shotblasting time. Inspection reports spanning over ten years have been crucial in tracking progress and confirming the efficiency of the implemented solutions.

Technical Case Study

The use of historical data and comparison with the new parameters were vital. The selection of the shotblasting media, adjusted to meet new demands, exemplifies Canam’s technical adaptability, backed by Winoa’s expertise.

Testimonials

“Thanks to the expertise and dedication of Winoa, we managed to not only understand but also improve our shotblasting process, ensuring consistent quality even under challenging conditions,” said André Bilodeau, technical director at Canam.

Conclusion

This case study exemplifies Winoa’s ability to provide comprehensive, tailored, and multilingual technical support. Together, we continue to seek innovative solutions, pushing the boundaries of what is possible in the surface preparation industry.

To learn more about our solutions and how we can help your business optimize its shotblasting processes, contact us today or visit our website for more information.

Contact your local representative

Call to action

"*" indicates required fields