Winoa-2Effe

Shot Peening Excellence

In India

Leading the Way in Peening

Who we are

Winoa-2Effe Private Limited is a joint-venture between Winoa, world leader of steel shot market, and 2Effe Engineering, the reference of shot-peening services in Europe.

- You are looking to out-source shot-peening process?

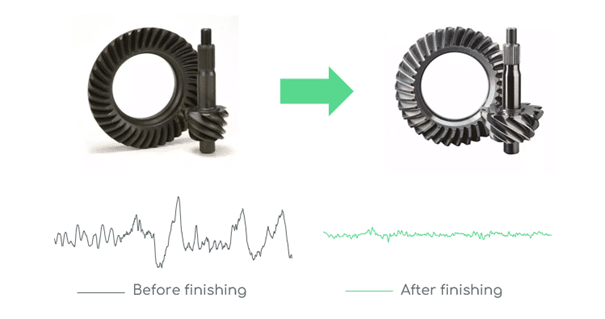

- You require mirror finishing process on intricated shape components?

- You need to assess residual stress through X-ray diffraction?

- You want to grow your team skills and knowledge on the shot-peening process?

We’ve got your back through our brand-new facility dedicated to shot-peening excellence in Maharashtra, at the heart of one of the largest industrial hub of India!

Our comprehensive range of services

Shot peen & finishing services

Peening

Polishing

X-Rays

Consulting

Training

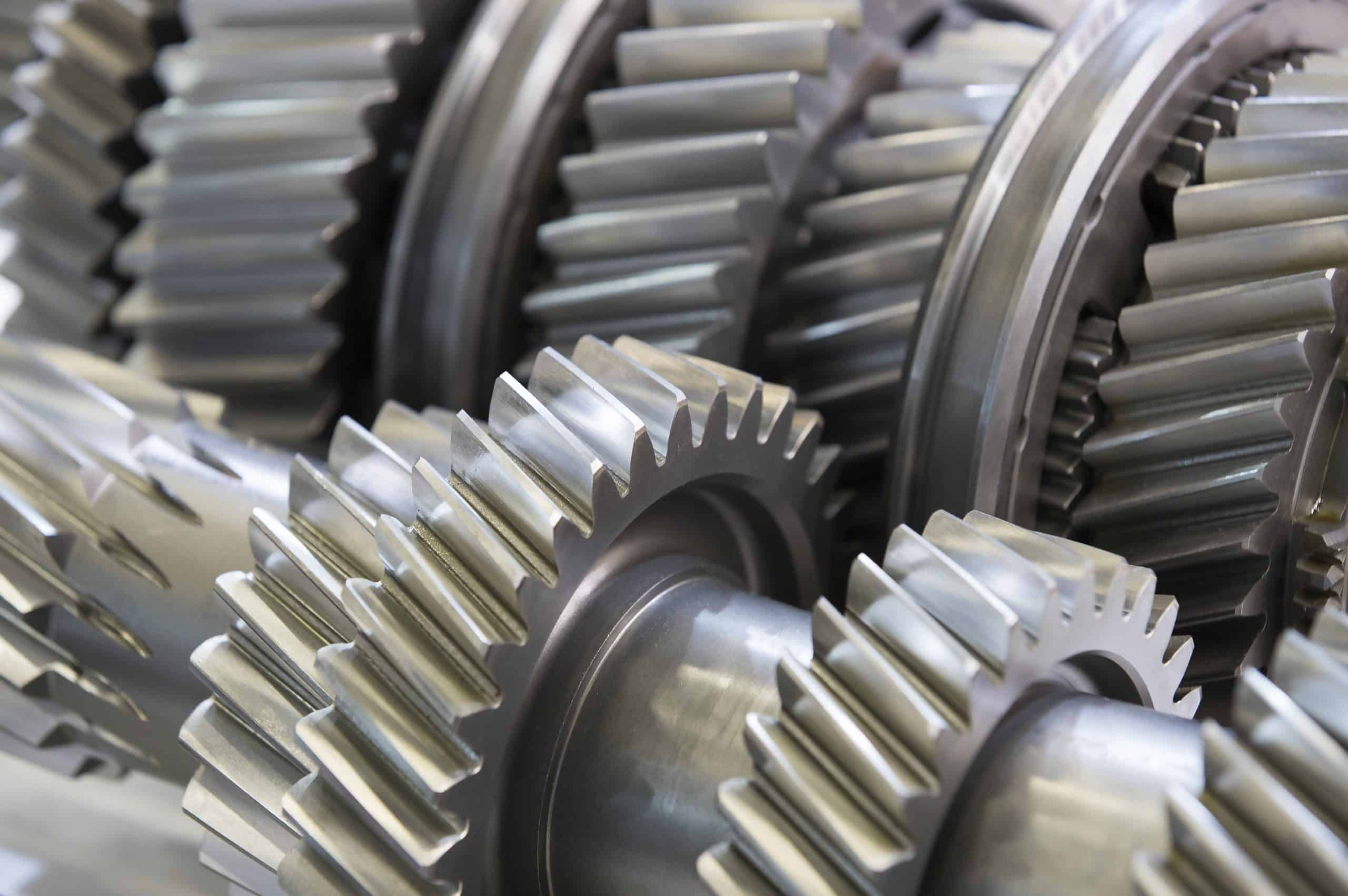

At Winoa-2Effe, we pride ourselves on offering specialized shot peening solutions tailored to the unique needs of the aerospace, automotive, and power generation industries. Our state-of-the-art technology and expert approach ensure optimal fatigue performance and surface enhancement for a variety of components. Discover our dedicated services and how they can transform your project:

Core Values of Winoa 2Effe

Excellence in Every Endeavor

Excellence Delivered

Quality at its pinnacle, striving without end.

Committed Nights & Days

Effort beyond hours, surpassing expectations.

Best in Class – Everyday

Improvement incessant, at the forefront constantly.

Accuracy with Precision

Attention to the finest detail, standards never compromised.

Evolving Passionately

Growth continuous, innovation limitless.

Our one-of-a-kind facility comprises:

A 15.000 sq. ft. shopfloor fitted with:

- Cleaning and degreasing machine

- 2 x wheel-blasting machines (hanger-type, 2 x 5,5 kW each)

- Manual air-blasting room (4 m x 4 m dimensions)

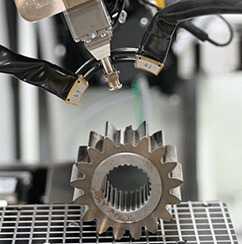

- Robotized air-blasting room (4 m x 4 m dimensions)

- 2 x vibratory finishing machines (410 liters capacity each)

Cutting-Edge Laboratories for Precision

Advanced Materials Analysis

A state-of-the-art metallurgical laboratory fitted with:

- Automatic samples preparation systems (cutting, polishing, mounting)

- ISO/ASTM certified perthometer

- ISO/ASTM certified Vickers hardness tester

- ISO/ASTM certified Rockwell hardness tester

- ISO/ASTM certified microscope with image analysis software

A X-rays diffraction laboratory fitted with:

- Electro-erosion system

- X-rays diffractometer

Fueled by our passion for excellence and the unrivalled shot-peening expertise of 2Effe Engineering team, this service center aims at bringing shot-peening excellence to India.

X-Ray Diffraction (XRD) Analysis Services

Enhancing material integrity through precise analysis.

Our Capabilities

- Residual Stress Analysis: Evaluate stress at and below the surface to ensure material reliability.

- Retained Austenite Analysis: Determine austenite content to optimize mechanical properties.

- Electro-Chemical Etching: Perform sub-surface analysis with a minimum increment of 15 μm.

- Standards Compliance: Adhere to ASTM E2860-20 and EN 15305:2008 standards.

- Certified Laboratory: Operate under ISO9001 certification for materials testing.

Our X-Ray Diffractometer

- Model: ENIXE from TNX s.r.l. (Italy), manufactured in 2024.

- X-ray Tube: Cr Kα anode with 4 W power.

- Ψ Range: From -45° to +45°.

- Φ Range: From 0° to 360°.

- Detector: Solid-state band detector 64×8 mm with 1280 active pixels (24×24 μm each).

- Alignment: Laser controlled.

- Analysis Capabilities: Biaxial stress, stress tensor, and retained austenite.

- Filter: Vanadium.

- Collimators: Available in 0.5 mm, 1 mm, and 2 mm sizes.

Service Offerings and 2025 Starting Prices

| Service | Description | Starting Price (₹) |

| Residual Stress Analysis (Surface) | Analysis at the material’s surface | 4,000 + GST |

| Residual Stress Analysis (Sub-surface) | Analysis below the material’s surface | 4,500 + GST |

| Retained Austenite Analysis | Determination of retained austenite content | 3,000 + GST |

Access our X-Ray diffraction analysis 2025 price list

Fill out the form below to download our prices

At Winoa-2Effe, we apply our shot peening expertise to a wide spectrum of industrial components, enhancing durability and performance. From automotive to aerospace, discover how our treatments fortify and extend the life of critical parts in various sectors.

Winoa-2Effe Pvt. Ltd.

RMK Industrial Park I, Gut No. 40,

Village: Navlakh Umbre Tal. Maval,

Pune 410506 (Maharashtra), India

For general inquiries:

Email: contact@winoa-2effe.com

To reach our General Manager, Joan Samuel:

Phone: +91 85 888 42 126

Email: Joan.samuel@winoa.com

Certifications

Have questions? Send us your thoughts and we'll get back to you promptly.

Contact Winoa-2Effe Today

"*" indicates required fields